Home / News / Market News

Exhibition Name:

2023 Electronica South China

Exhibition Date:

2023.10.30 - 11.1

Exhibition Address

Shenzhen World Exhibition & Convention Center

5G41

Zmotion will attend "2023 Electronica South China" in 2023.10.30 - 11.1, a series of high-performance real-time hardware, software products and solutions that are researched and developed by Zmotion will be shown in 5G41.

Zmotion focuses on motion control product's development all the time, and we aim at promoting electronic semi-conductor automation equipment, accelerating market importing. Our Zmotion motion control products not only can be applied in most of semiconductor applications, but also provide faster, more accurate, and more intellectual motion control solutions for semi-conductor users.

During 10.30 - 11.1, in Zmotion 5G41, you could feel real-time kernel high-speed data interaction, and technology optimization on traditional solutions. The most important, you could know deeply how to enhance production efficiency and quality, how to reduce cost. In addition, Zmotion prepares one new interaction mode for you this time, you will have a chance to win great value gifts, welcome!

Zmotion in Exhibition

2023 Electronica South China

In this fair, Zmotion will display several kinds of high real time products and motion control solutions.

VPLC711 -- Vision Motion Controller

high-performance x86 platform Windows real-time vision motion controller develops innovative intellectual manufacture.

motion control: 6-64 axes (pulse + EtherCAT bus)

vision: real-time kernel MotionRT7 is built in, the third-party vision software also is valid

IN & OUT: 20 general inputs (10 are high-speed) and 20 high-speed outputs

multi-core parallel operation: process core tasks of automatic equipment in motion control and machine vision effectively

PSO: multi-dimensional position synchronous output PSO, precisely control dispensing and laser energy in the continuous processing process

Open IPC real-time soft controller / soft PLC: integrate motion control + machine vision solution flexibly

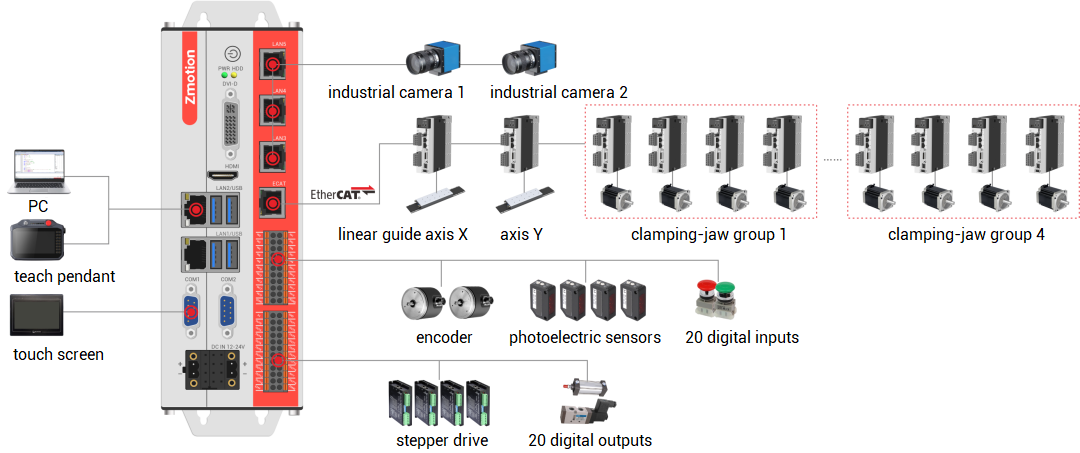

(1) high-speed special-shaped plug-in machine

This solution uses our Zmotion vision motion controller VPLC711.

VPLC711 supports multi-core parallel operation ability, which can process motion control and machine vision core tasks of automatic equipment effectively. Then, it ensures that some key steps in plug-in technology can be completed in high-speed and high-precision, such as, path planning, data interaction, element plug-in, cramp control, workpiece uninstall, etc.

--application advantages--

250us EtherCAT synchronous period achieves multi-axis high-speed and high-precision motion control.

torque precisely controls the clamping force of the jaws to prevent workpiece damage or loosening.

flexibly expand through EtherCAT, multi-axis linkage and multi-workpiece joint can be achieved, then production efficiency is improved.

path planning can optimize movement trajectory of plug-in, promote plug-in efficiency and speed.

vision fly-shooting can trigger plug-in element to make camera take the photo instantly.

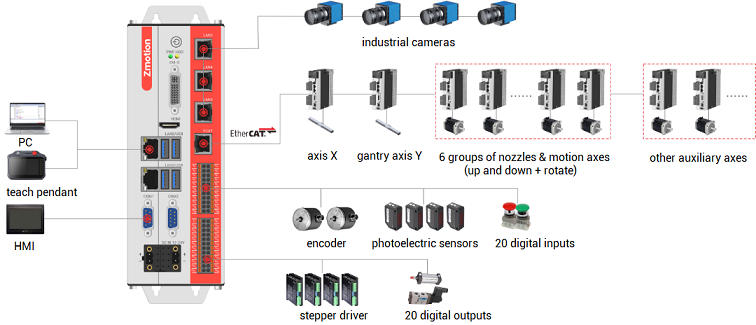

(2) High-precision auxiliary SMT

This solution uses our Zmotion vision motion controller VPLC711.

VPLC711 supports EtherCAT bus communication and multiple real-time motion control functions, including position latch, multi-dimensional high-speed hardware position comparison output PSO. That is, it can feedback real-time position of motion axes, then it achieves multi-axis synchronous control and high-speed data transmission, ensuring that auxiliary materials can be mounted on the target substrate with high placement accuracy and speed during the transmission, loading and unloading, visual positioning, and placement processes.

--application advantages--

250us EtherCAT synchronous period achieves multi-axis high-speed and high-precision motion control.

path planning function optimizes nozzle's movement trajectory, then mounting efficiency and speed are promoted.

high-speed vision fly-shooting function can rapidly position and correct the auxiliary materials on 6 nozzles to achieve continuous production.

the torque control function accurately controls the force applied by the nozzle when pressing down the auxiliary materials to prevent the auxiliary materials from being crushed and deformed.

flexibly mount multiple auxiliary materials on a single board or multiple panels without additional fixtures or adjustments, providing convenience for the operation and placement of target substrates of different specifications.

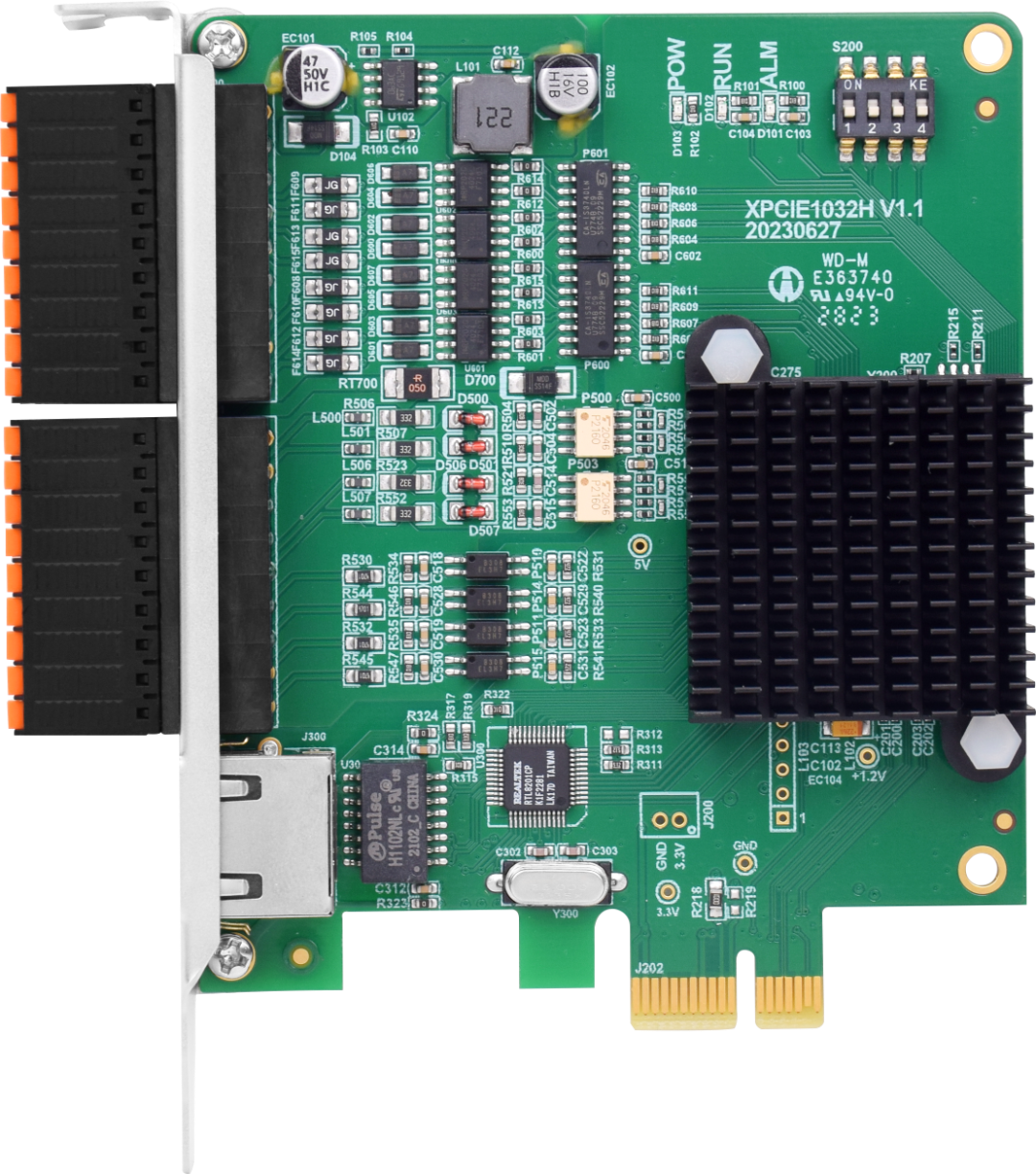

XPCIE1032H -- Ultrahigh Speed PCIe EtherCAT Real-Time Motion Control Card

XPCIE1032H matches with Windows motion control real-time kernel MotionRT7 to achieve real-time control system under Windows that cannot be realized by traditional PCI/PCIe.

motion control: 6-64axes (pulse + EtherCAT bus)

EtherCAT bus minimal period: 250us

8 high-speed inputs and 16 high-speed outputs PSO: meet us level real-time precise control of multi-channel for semi-conductor devices and screening machines

multi-core parallel operation: process core tasks of automatic equipment in motion control and machine vision effectively

data interaction: instruction calling speed is faster 10 times than traditional PCI/PCIe

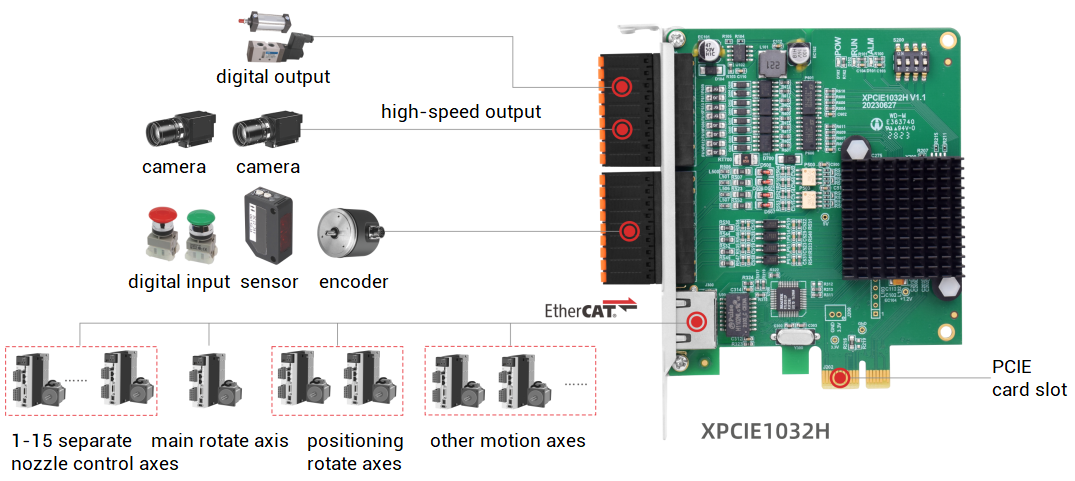

(1) Turret test sorting machine

This solution uses ultrahigh speed PCIe EtherCAT real-time motion control card XPCIE1032H.

XPCIE1032H is with multi-core parallel operation ability that can process motion control and vision core tasks. In addition, multiple high-speed IOs and EtherCAT bus communication can achieve multi-axis synchronous control and high-speed data transfer, which ensures that several processes test, sort, collect, and tape the chips sequentially within the rotation cycle, so that the entire testing and sorting process runs coherently, efficiently, and stably.

--application advantages--

test & sort high-speed and stably, productivity can reach 53K/H

rapid motion mode switching (position or speed) achieves high-precision control

250us EtherCAT synchronous period controls multiple nozzles to run up and down quickly and separately, efficiency can be promoted

customized solution is valid, which means you can assign IO signals freely and expand control axes flexibly according to the specific needs

compare to traditional PC + motion control card solution, this XPCIE1032H solution is more stable, with faster interaction speed, about 10% speed can be enhanced

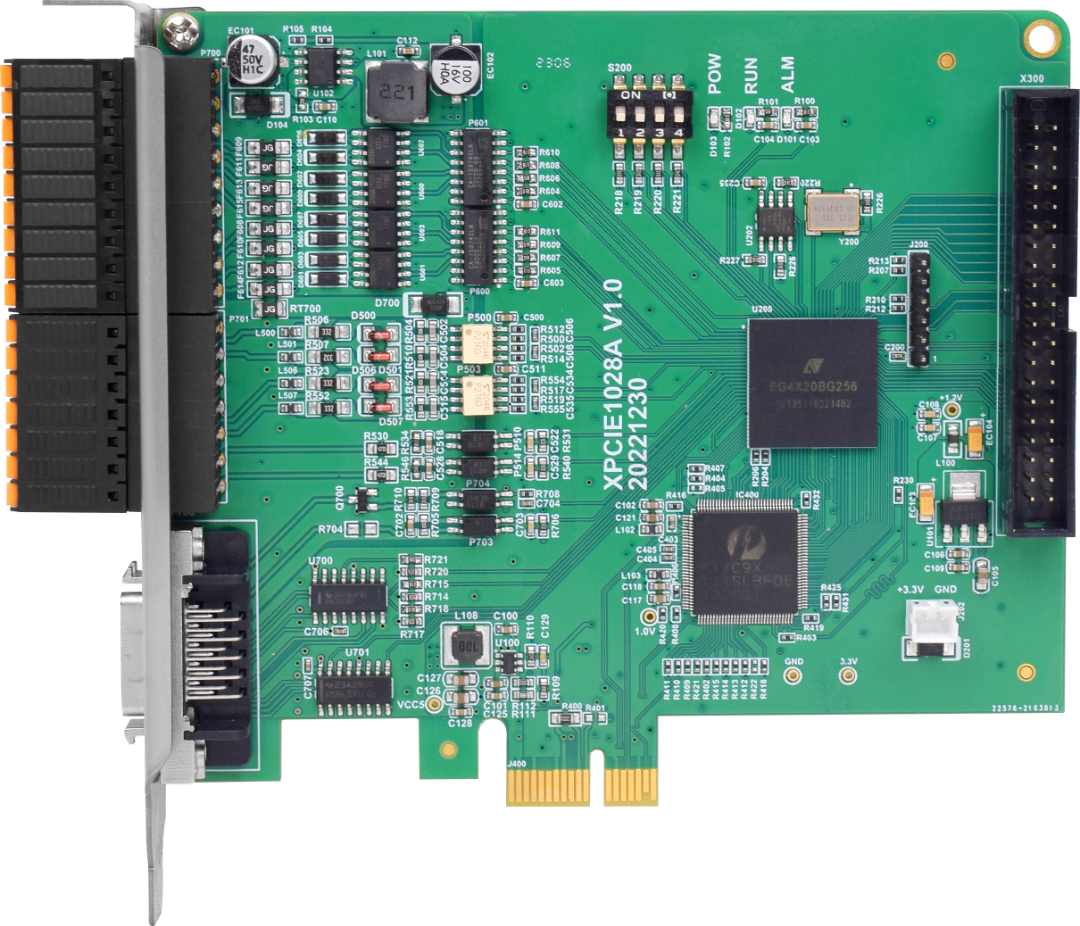

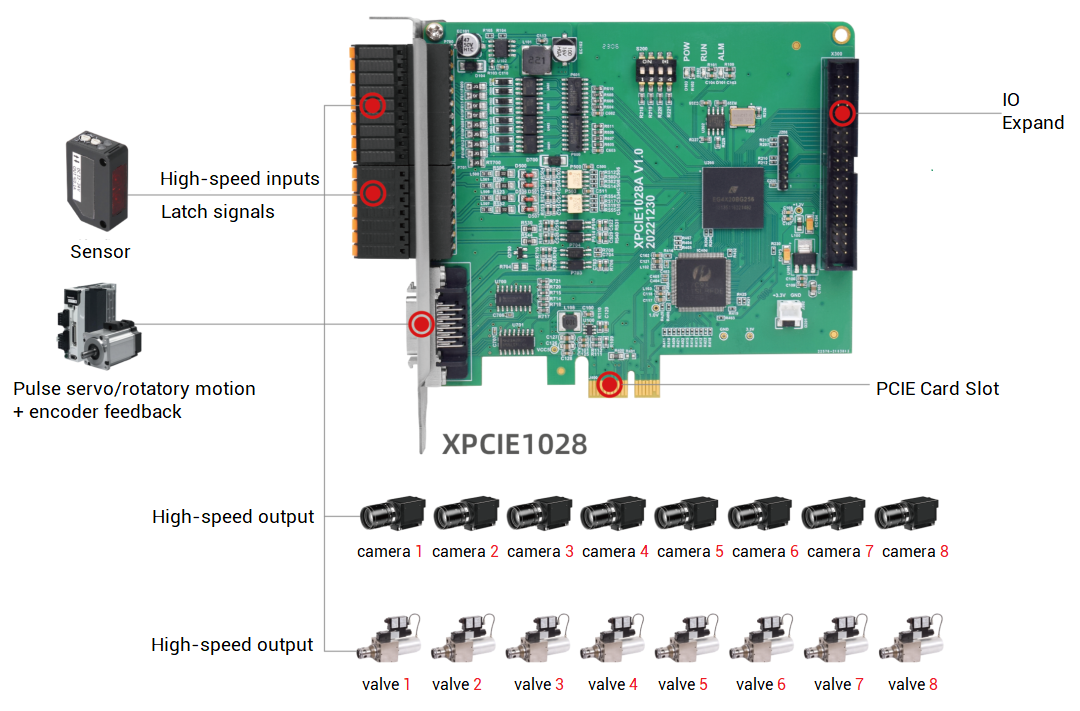

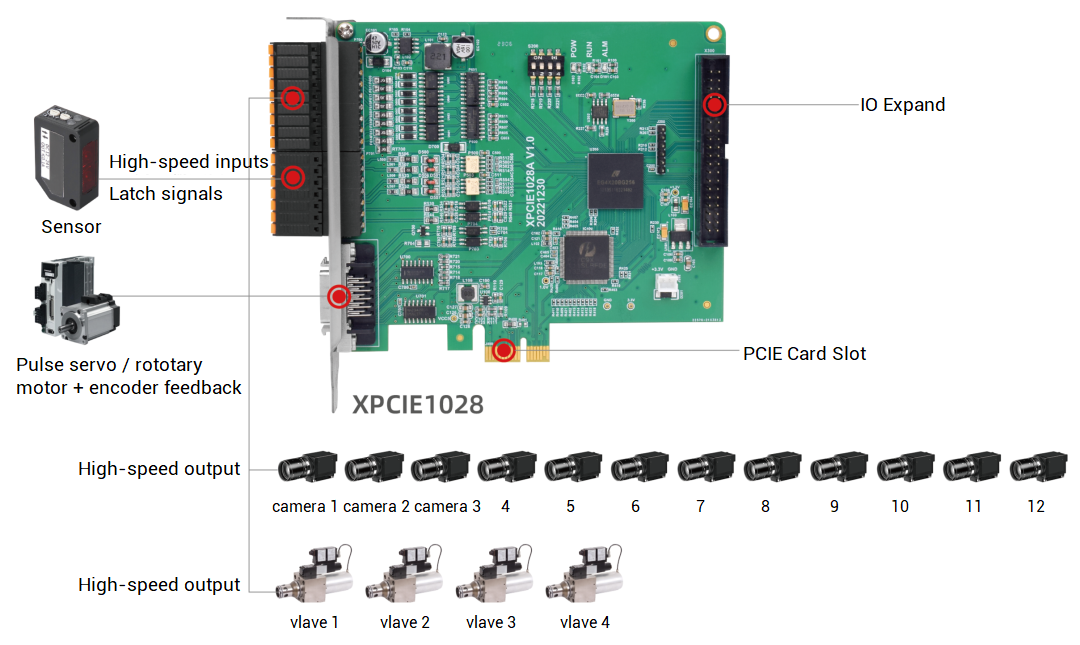

XPCIE1028 -- Ultrahigh Speed Control Card Specialized for Vision Screening Machine

XPCIE1028 motion control card is a PCI Express® bus motion control card specially designed by Zmotion Technology for high-speed visual screening equipment.

It can control multiple stepper motors or digital servo motors, including several cameras and blowing ports.

multiple hardware position comparison trigger efficiency can reach15000 + pcs/min

standard PCIe interface and core interaction brings faster velocity

there are12 inputs (8 high-speed) and 16 outputs (16 high-speed)

cameras and blowing ports can be set to OUT1-OUT16 freely

support specialized pulse output and encoder input

several kinds of host computer programming language can be used to develop

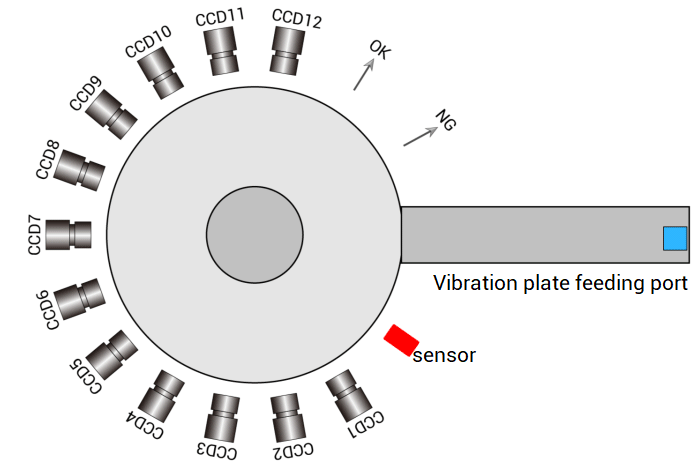

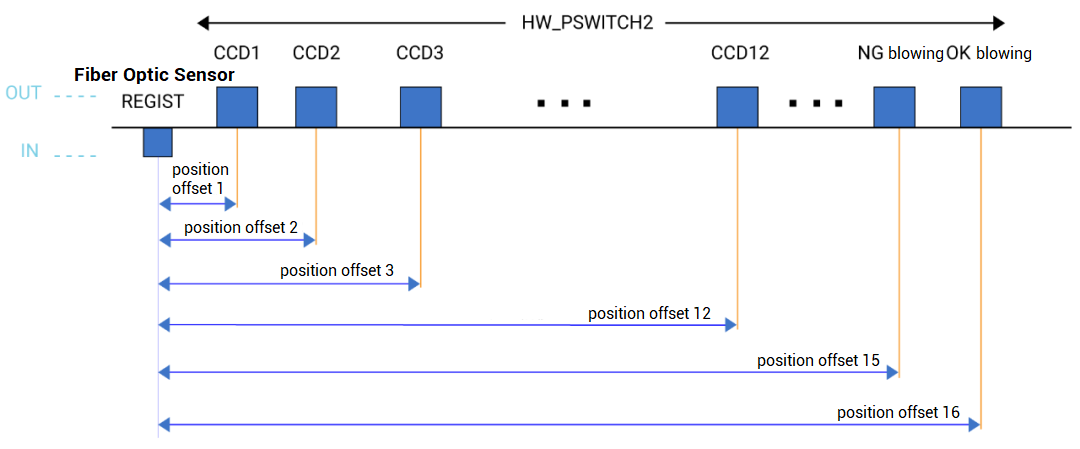

(1) High-speed visual screening machine

This solution uses Zmotion high-speed PCIe EtherCAT real-time motion control card XPCIE1028.

In addition, Zmotion provides specialized screening machine debug software, 15000 pcs/min IO trigger detection speed can be achieved. Specifically, it only needs to set basic parameter, combining with image acquisition hardware and vision processing software, full-automatic high-speed vision filtering development and debug can be realized rapidly.

--application advantages--

high-speed filtering: 15000+ pcs/min hardware position comparison triggering

motion control: no need to program, easy to set parameters

quality: filtering in auto-size, low

heartbeat interaction: safer operations

API interface: there are specialized API function interfaces for screening machine

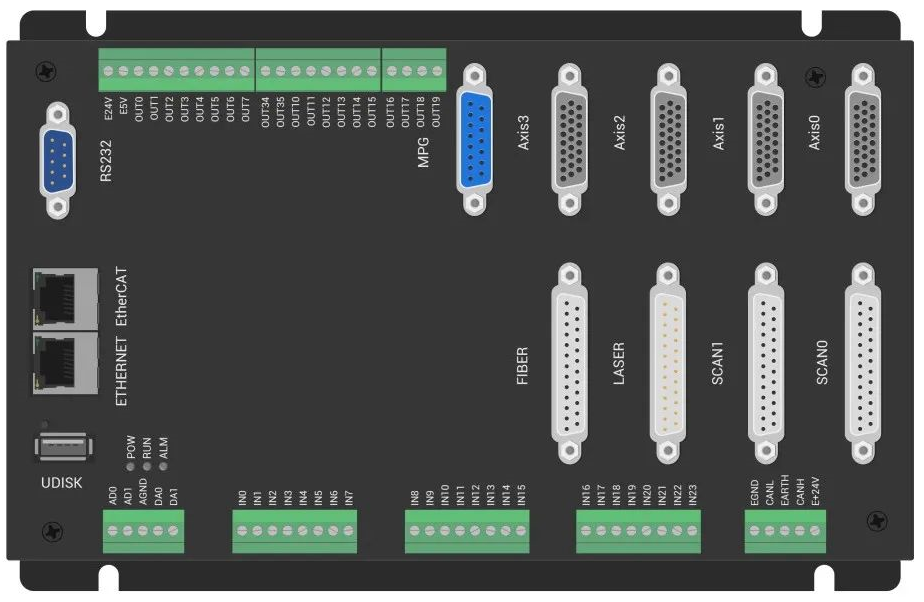

ZMC408SCAN-V2 -- Open Laser Galvanometer Motion Controller

An independent laser galvanometer motion controller integrates laser control, galvanometer control and bus axis / pulse axis control, which can help you high-speed high-precision EtherCAT motion control + laser galvanometer solutions.

4 differential pulse axes + 1 specialized handwheel

2 SCAN interfaces with feedback, 1 LASER and 1 FIBER laser power interface

support 1D/2D/3D PSO function, then achieve vision fly-shooting, precise dispensing, and laser energy control

there are 24 general inputs and 20 general outputs, and 4 are high-speed color code latching, 4 are PSO outputs and 8 are PWM outputs

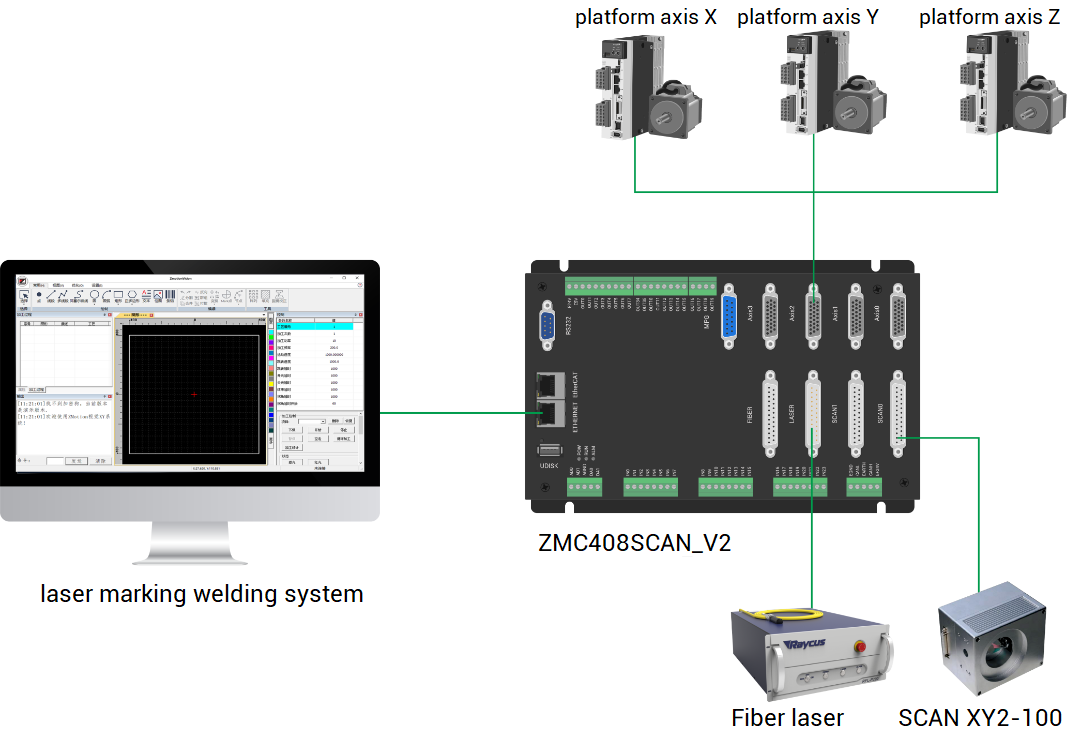

(1) Power battery module connection piece welding application

This solution uses Zmotion open laser galvanometer motion controller ZMC408SCAN-V2 to achieve precision laser energy control and welding trajectory planning, at the same time, it can optimize laser welding technology process, then improve processing efficiency and quality.

--application advantages--

linkage interpolation of SCAN axis and servo axis

flexible laser power adjustment, that is, corresponding laser parameters can be modified freely according to laser type and wiring configuration.

set processing speed and delay technology parameters to control welding accurately for different welding materials and needs

develop through C++, C#, etc., specified laser function library and applications are provided, it's convenient for device system manufactory to develop rapidly

spiral trajectory welding function: through the high-speed rotation of the light spot along the welding direction, different weld depth-to-width ratios can be achieved without changing the external light path conditions

Welcome to 2023 Electronica South China, Zmotion is waiting for you at 5G41.

In this fair, there are rich application solution demo showing, product introduction, Interactive lottery, etc., and if you are interested in our Zmotion motion control products or solutions, welcome to communicate with us at 5G41 or contact us online.

Let's explore advanced technology and innovative application for electronic semiconductor automation equipment together!