Home / News / Market News

Fair Name:

Chengdu International Industrial Fair (abbreviation: CDIIF)

Fair Date:

2024.4.24-4.26

Fair Address:

Western China International Expo City

Booth No.:

15H-A008

In 2024, CDIIF will be held in China (Chengdu) Western International Expo City during 4.24-4.26.

Nowadays, market competition becomes fierce increasingly. Do you find some different motion control solutions that can achieve higher efficiency and better effect, and then operation cost is reduced, the production line is more intelligent?

Welcome you to 2024 CDIIF, Zmotion will answer the question. Because Zmotion knows there are many kinds of challenges for enterprises in the process of high-speed & high-precision production, then, based on this situation, Zmotion focuses on developing flexible and personalized intelligent manufacture solutions for multi-area users.

Zmotion booth No. is 15H-A008. In this CDIIF, Zmotion will show you how general motion control functions of Zmotion software and hardware products are used to achieve high-speed, high-precision motion control solutions in all kinds of dispensing, denture processing, robot auxiliary processing. Including how to promote close connection and efficient collaboration in each production process for multi-area. Most importantly, how to help enterprises improve efficiency and quality synchronously, then reduce the cost. In this fair, Zmotion invites you to experience our motion control products and solutions.

Fair Key points

2024 CDIIF & ZMOTION

1. UVW Dual-Len Vision Alignment Solution on PCB Board

--Solution Introduction--

As we all known, PCB production involves many technology steps, like, multi-layer board superposition, element placement. Each placement precision is extremely important, which affects the PCB board processing quality directly.

This solution combines Zmotion ZVision (RTvision) image processing algorithm with UVW alignment platform. For hardware, VPLC7XX series vision motion controller is used. In this way, this solution can realize high-speed and high-precision dual-Len vision positioning & correction for PCB board. Namely, one simple operation can ensure production efficiency and processing quality.

--Hardware: VPLC7XX Vision Motion Controller--

One EtherCAT vision motion controller based onx86 structure, it supports offline running (without PC).

There are rich motion control and vision control functions, then configuration process can be simplified a lot.

Data interaction speed is rapid, which means time and cost are reduced obviously, and project efficiency is promoted.

Convenient to install and remove, and it only needs a small space so that it can be integrated with other control components easily (servo drive, sensor).

This is one vision + motion control solution that is integrated by real-time soft controller / PLC in the form of integration and openness.

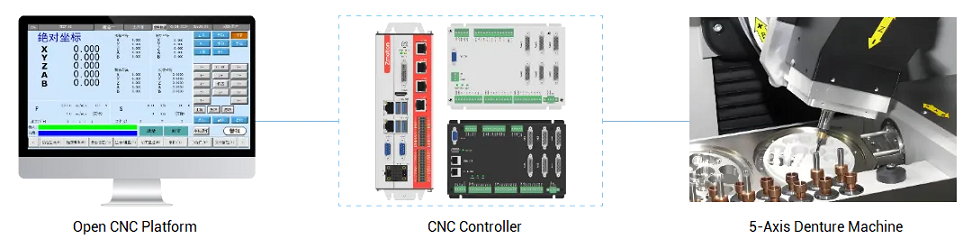

2.5-Axis Denture Machine CNC Processing Solution

--Solution Introduction--

This solution uses Zmotion technology open 5-axis linkage CNC system with 4-axis / 5-axis denture machine tool. In denture processing, this solution achieves precision engraving and grinding control, that is, it ensures that the height of denture conforms to ergonomics, and ensures the comfort and durability.

This solution avoids technical blockade and product supply problem effectively because of 100% research and development on system structure and algorithm.

Therefore, this intellectual motion control solution is mainly for denture medical equipment, then, the market share of Zmotion in the medical equipment market is increased.

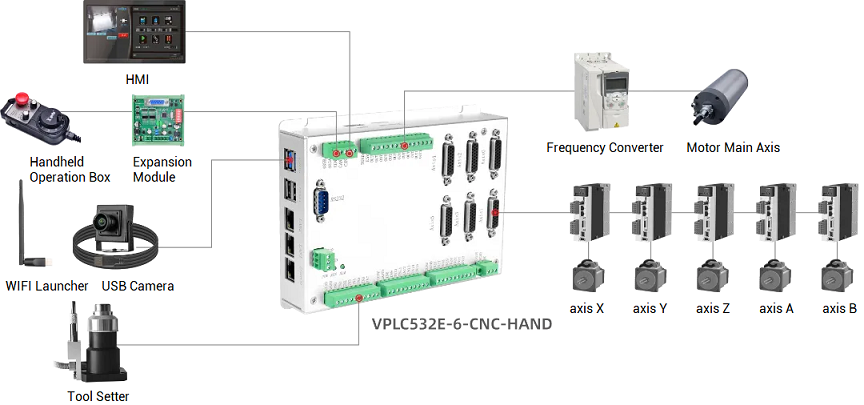

--Hardware: VPLC532E Vision Motion Controller--

One EtherCAT vision motion controller based on Linux structure, it supports offline running (without PC).

There are rich motion control and vision control functions built in, then configuration process can be simplified a lot.

Tool lifetime can be watched, and it supports automatic tool changing, and tool positioning functions.

Support remote device visualization interaction management, including remote monitor, then it can maintain in time.

WIFI net card can be configured together for data interaction and processing file interaction between CAM software and system by WIFI.

HMI system is suitable for beginners to operate control software easily.

There is one full-aspect protection mechanism, which includes low air pressure alarm, cooling water failure alarm, tool setting alarm, tool return detection alarm, axis alarm, and tool life alarm.

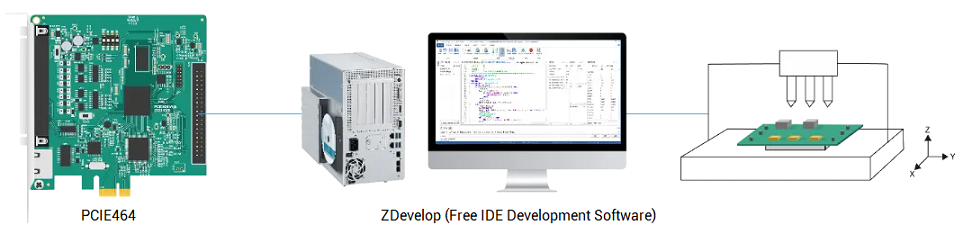

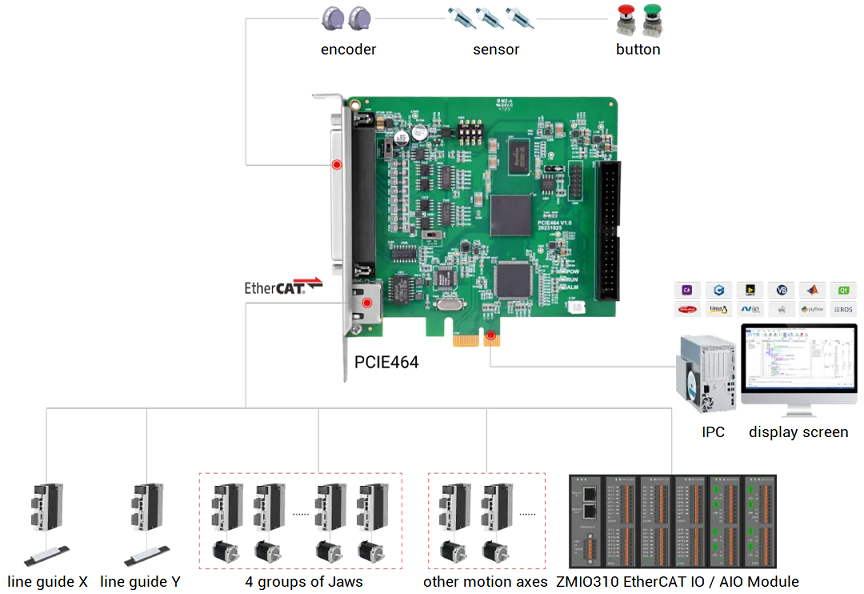

3. High-Speed Special-Shaped Plug-In Machine Solution

--Solution Introduction--

This solution uses XY linear motion platform, transfer device, feeding equipment and other core control modules, and matches with Zmotion super-high-speed real-time PCIe EtherCAT control card PCIE464, then synchronous control & high-speed data transfer can be achieved for multi-group working heads.

In this solution, it can suit to elements of different specifications (all kinds of shapes & sizes), then each technology process in the whole plug-in can be completed in high-speed and high-precision (from path planning, parts plug-in, clamping control to workpiece uninstall). Obviously, production period can be reduced a lot, and production efficiency and quality can be optimized.

--Hardware: Super-High-Speed PCIe EtherCAT Control Card PCIE464--

Motion Control: 6-64 axes (pulse + EtherCAT bus)

8 High-Speed Inputs & 16 High-Speed Outputs PSO: achieve us level real-time precise control in multi-independent-channel for 3C electronics, and semi-conductor devices.

Motion Control Real-Time Kernel: MotionRT7 is built internally

Multi-Core Parallel Operation: process core tasks of automatic equipment in motion control and machine vision effectively

Data Interaction: instruction calling speed is faster 10 times than traditional PCI/PCIe.

4.High-Speed Vision Screening Machine Solution

--Solution Introduction--

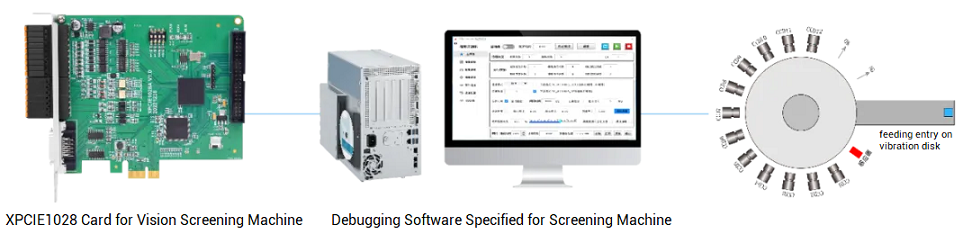

This solution uses core system components, such as, a high-transparency glass rotating platform, flexible feeding device and blowing device, and matches with Zmotion high-speed PCIe EtherCAT real-time motion control card XPCIE1028

In addition, Zmotion provides on debugging software that is specified for screening machine, 15000 pcs/min IO trigger detection speed can be achieved. Specifically, it only needs to set basic parameters. And the image acquisition hardware and vision processing software are combined, then it can realize full-automatic high-speed vision filtering development and debugging rapidly.

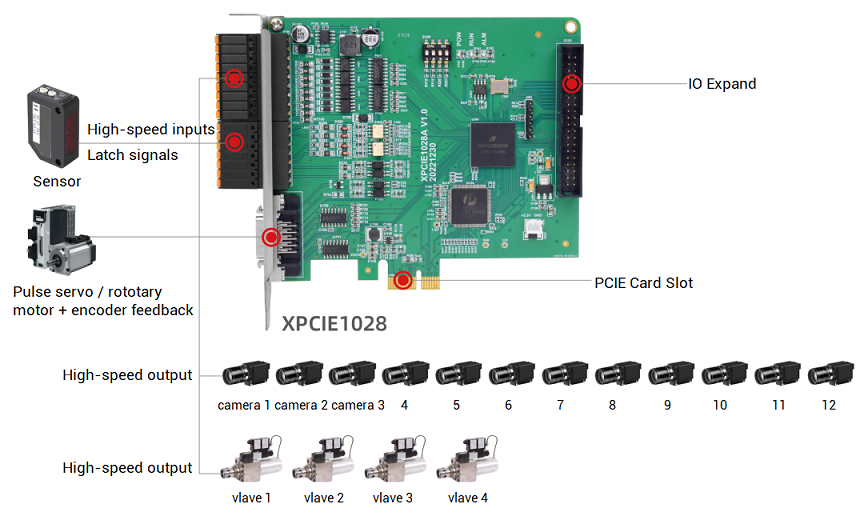

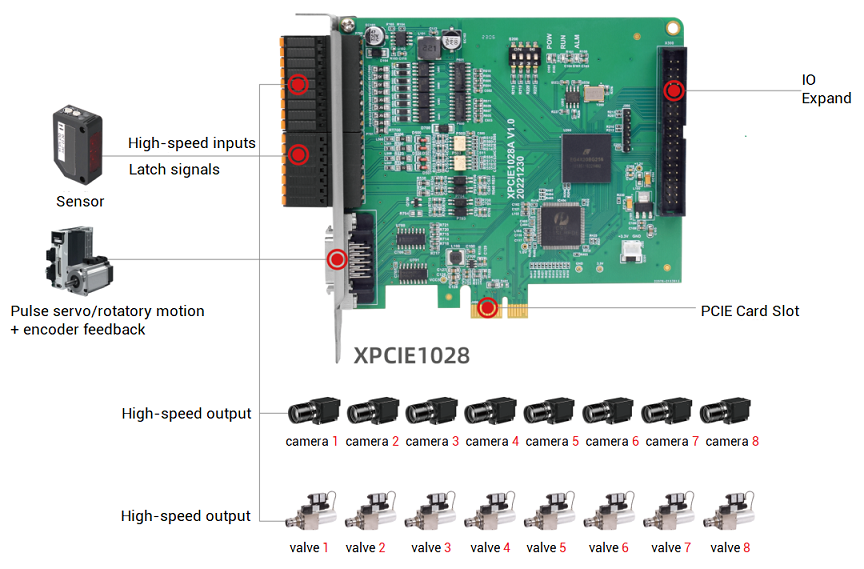

--Hardware: Super-High-Speed PCIe Control Card XPCIE1028--

hardware solution 1: XPCIE1028 & high-speed vision screening machine --12 cameras + 4 air valves

hardware solution 2: XPCIE1028 & high-speed vision screening machine -- 8 cameras + 8 air valves

Multi-channel hardware position comparison trigger efficiency can reach15000+pcs/min.

There is one standard PCIe interface for kernel interaction, the velocity is faster.

Be with 12 inputs (8 high-speed) and 16 outputs (16 high-speed), and these 16 high-speed outputs can be assigned as cameras or blowing ports freely.

There are specialized pulse output and encoder input interfaces.

Support multiple host computer languages programming.

5.Laser Motion Control Solutions

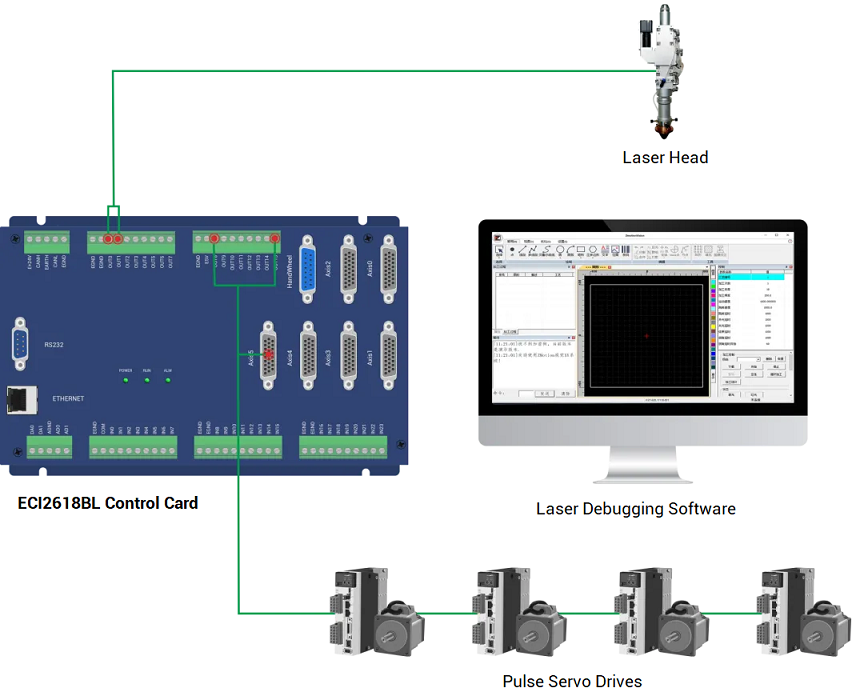

A. Laser Processing Solution by ECI2618BL Motion Control Card

Laser processing system based on ECI2618BL motion control card is mainly used for metal cutting, and laser welding. That is, ECI2618BL controls motor to achieve fiber laser head to move rapidly. Then, it can be seen that this laser control card suits to cutting and welding because it can run a big range.

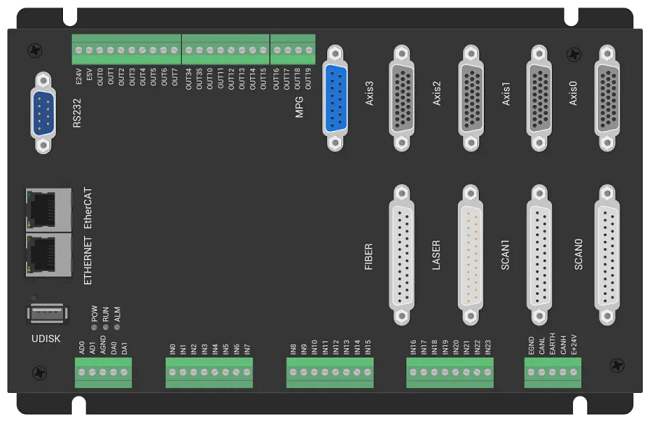

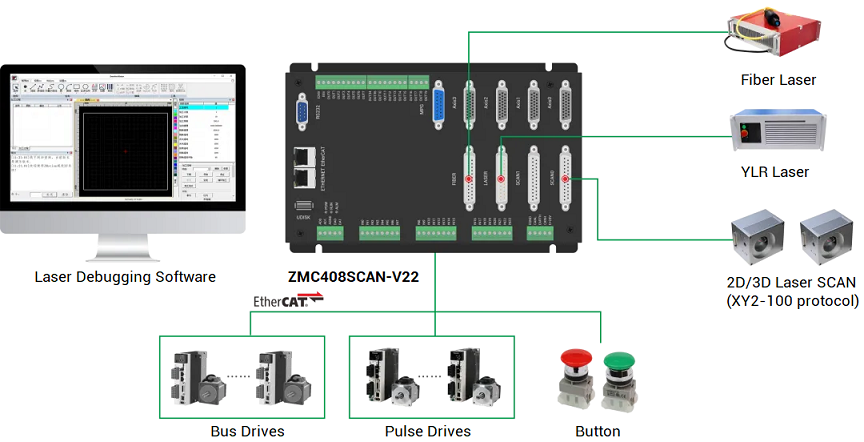

B. Open Laser SCAN Control Solution by ZMC408SCAN-V22

Open laser galvanometer control solution based on ZMC408SCAN-V22 is mainly applied in non-touch laser processing, for example, high-speed marking, laser clearing, precise cutting, precise welding. That is, it changes laser direction through high-speed vibrating lenses, and then it can achieve high-speed and high-precision laser processing. In a short, ZMC408SCAN-V22 controller can be applied in high-speed & high-precision laser control + SCAN control + motion control.

Welcome you to be present at 2024 Chengdu International Industrial Fair (CDIIF), and welcome to Zmotion booth (15H-A008). Let's experience soft and intelligent applications brought by high-speed and high-precision motion control solutions.

Hope to see you, and hope to communicate with you.