(1) Introduction

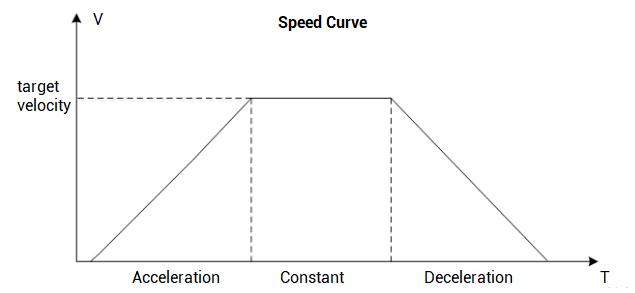

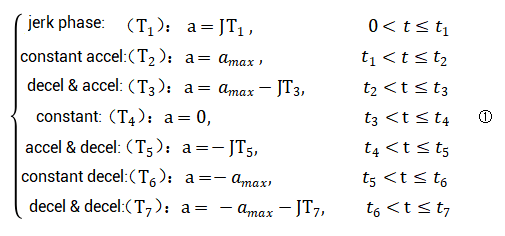

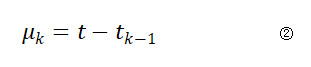

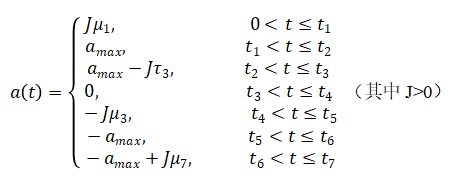

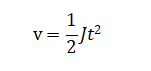

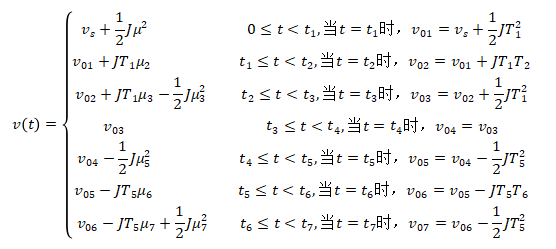

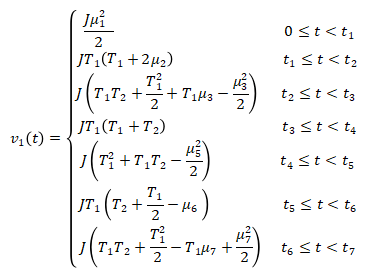

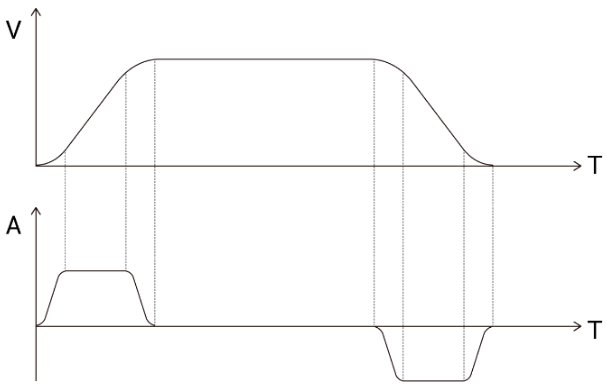

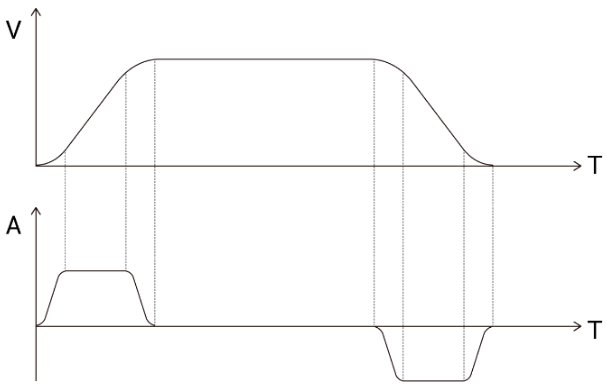

The acceleration and deceleration curve type can be set through the VP_MODE command. And there are multiple modes to choose, S-curve and SS curve can be set to make the trapezoidal curve smoother. This instruction is generally used in the axis parameter initialization program and can be used together with the SRAMP instruction. When VP_MODE is mode 0, the value set by

SRAMP takes effect.

Syntax: VAR1 = VP_MODE or VP_MODE(axis)=mode

mode: mode selection

The VP_MODE mode is as follows.

--Mode 0--

By default, use SRAMP to set the S-curve.

--Mode 4--

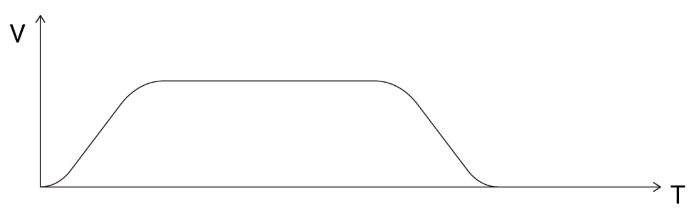

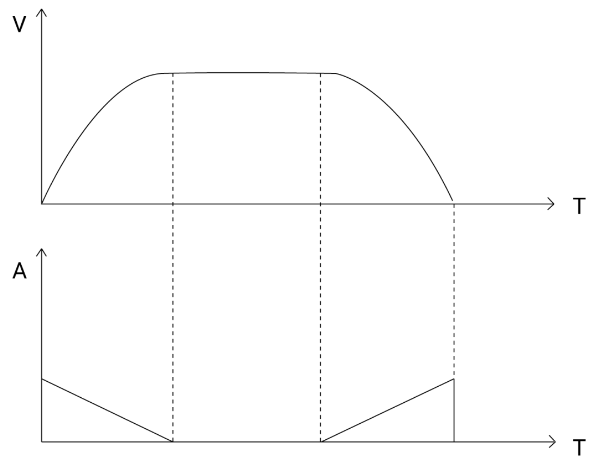

The maximum acceleration is at the start, and the acceleration gradually becomes 0 when the maximum speed is reached. The S and SS curves are shown below.

This mode is suitable for high-speed start-stop processing occasions that do not require impact.

--Mode 6--

A new type of SS curve, a curve type with continuous jerk, SS mode will increase the deceleration time by 87% compared with T-shaped deceleration. This mode only takes effect in the deceleration phase, and the acceleration phase takes effect in mode 0, which is convenient for continuous small line segment interpolation.

This mode is suitable for processing occasions where the machine starts at high speed and stops smoothly.

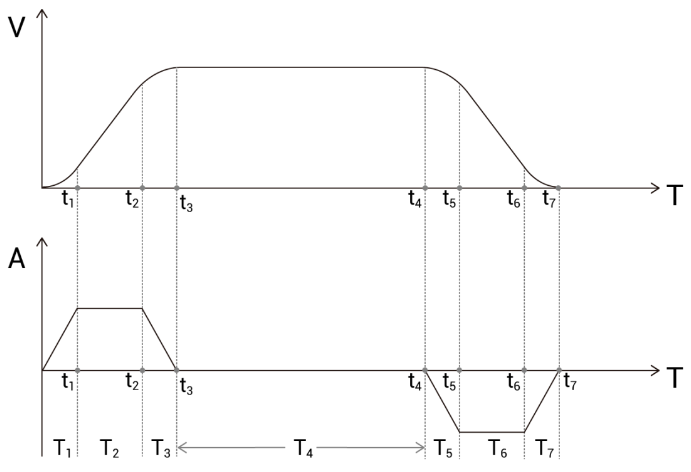

--Mode 7--

New type SS curve, curve type with continuous jerk. Dynamically modifying the axis parameters or continuous interpolation may cause the jerk to be uncontinuous. At this time, it will switch to mode 0, so it is recommended that SRAMP also set an appropriate value.

This mode is suitable for shock-free processing occasions with high precision and stable start-stop speed.

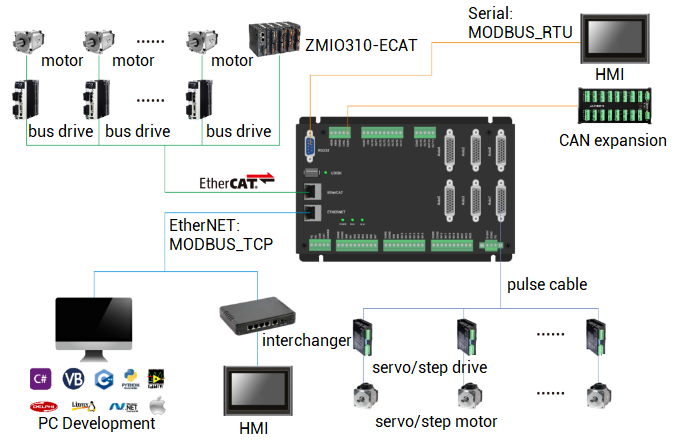

(2) Examples & Routines

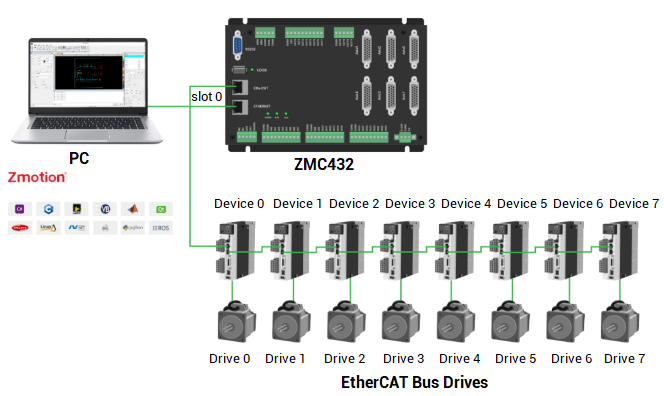

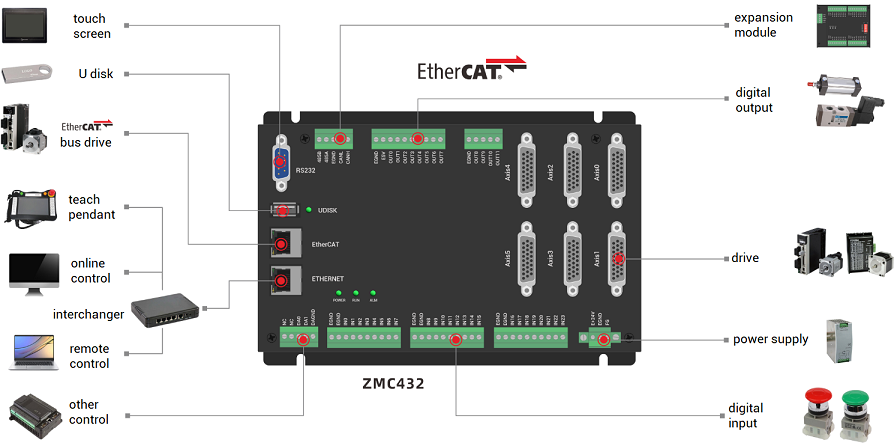

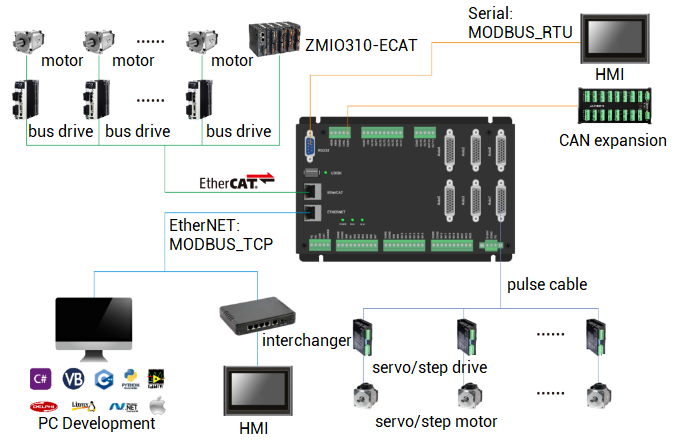

Following all routines can be achieved through ZMC432 controller.

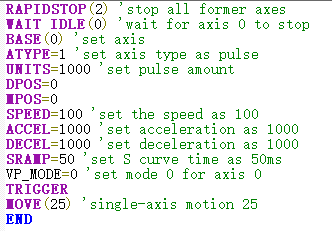

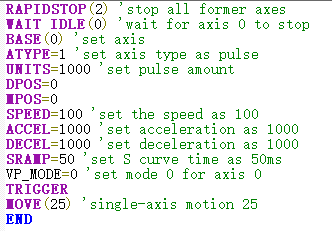

--set VP_MODE as mode 0, take the single-axis motion as the example--

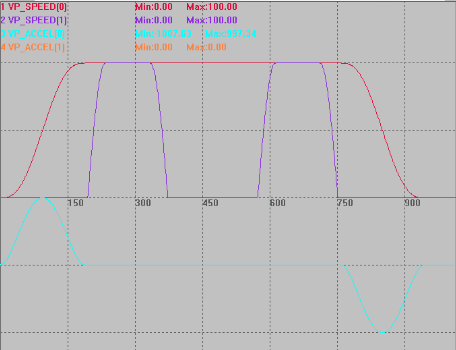

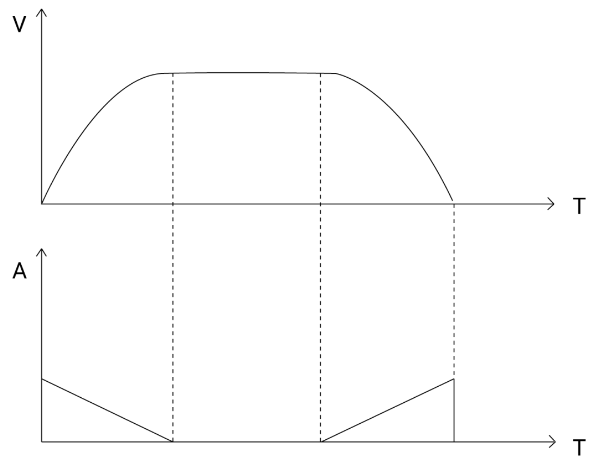

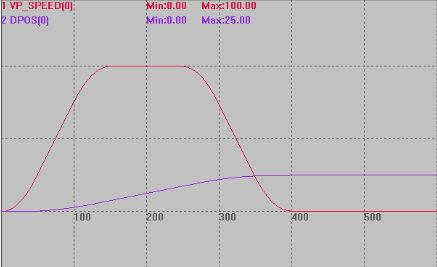

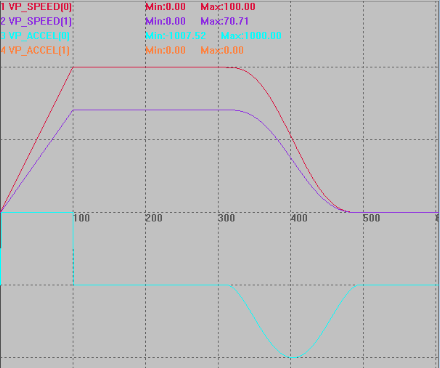

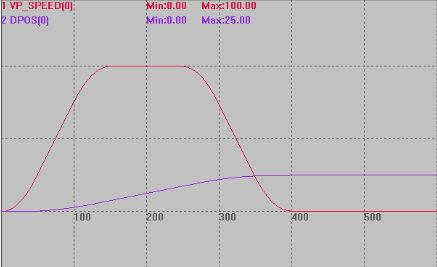

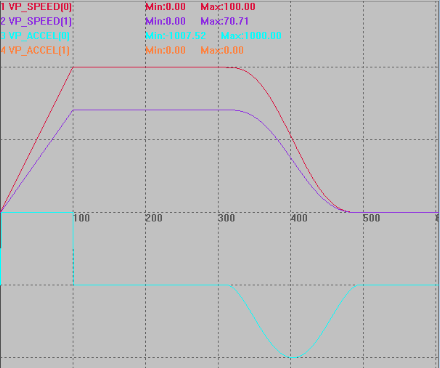

When SRAMP=50, the speed and acceleration curves are shown in the figure below, which are smoothed in the acceleration and deceleration phases respectively, and the movement time will be extended accordingly. It can be compared with the graph when SRAMP=0.

When SRAMP=0:

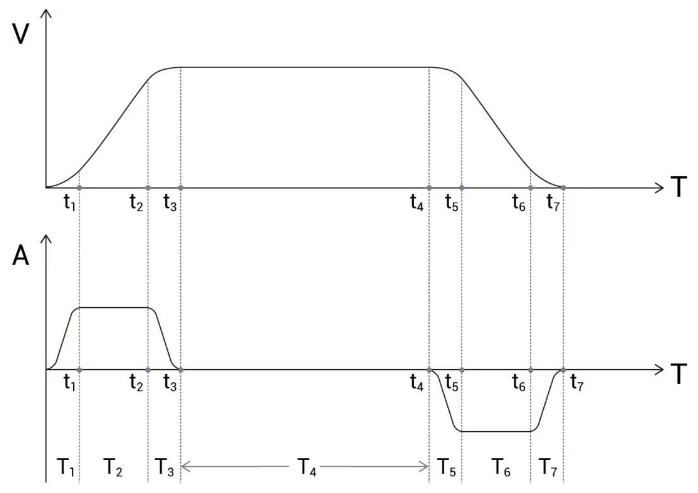

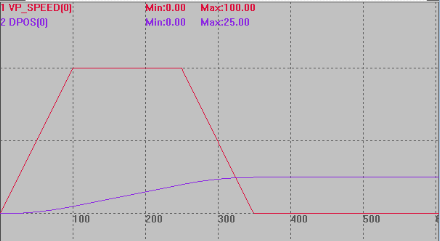

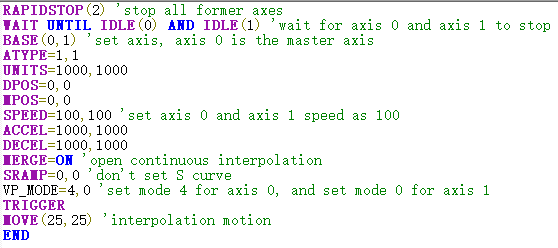

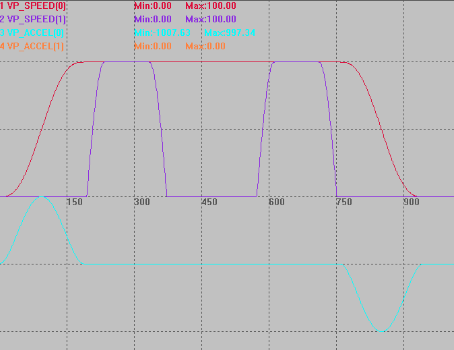

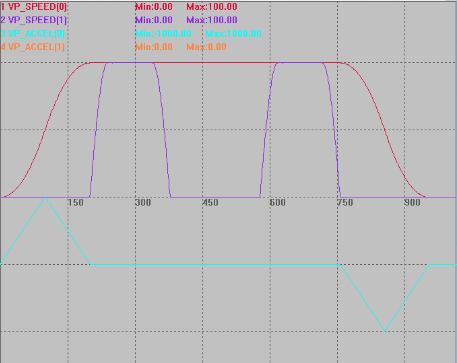

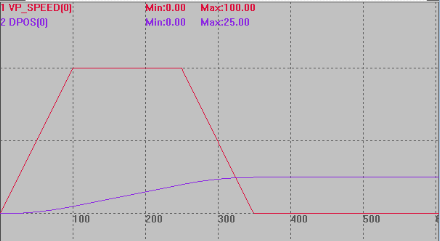

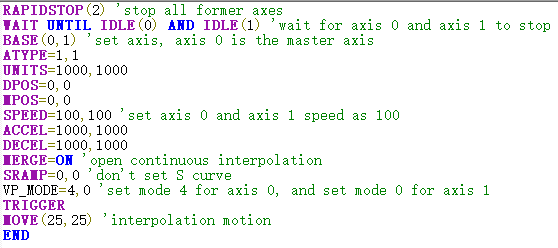

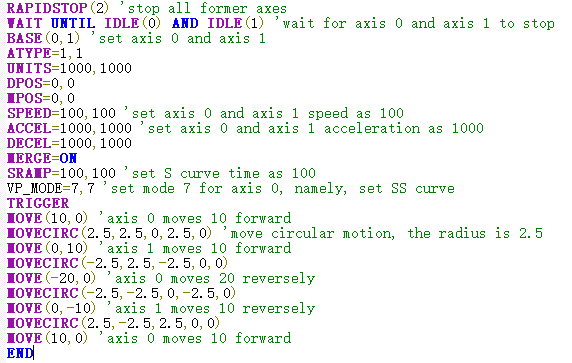

--set VP_MODE as mode 4, take multi-axis linear interpolation as the example--

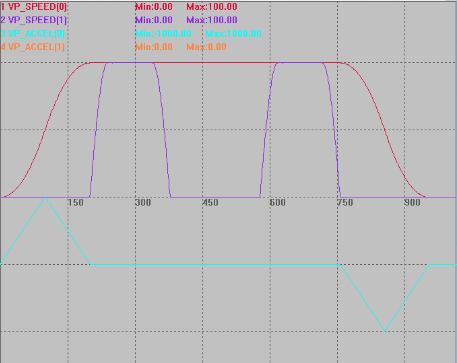

Under the above configuration, axis 0 adopts VP_MODE mode 4, starts to move with the highest acceleration and decreases to 0. This mode is suitable for occasions requiring quick start and stop.

Note: since this movement is an interpolation movement, axis 0 is the main axis, so the speed and acceleration curves can be based on the main axis. The VP_ACCEL data source needs to be manually input to collect changes in acceleration values under the S-curve and SS-curve.

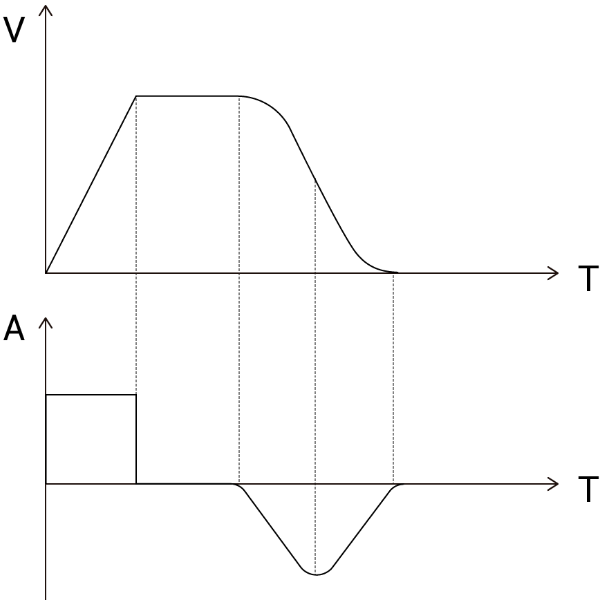

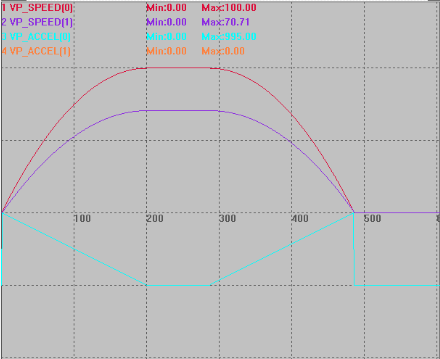

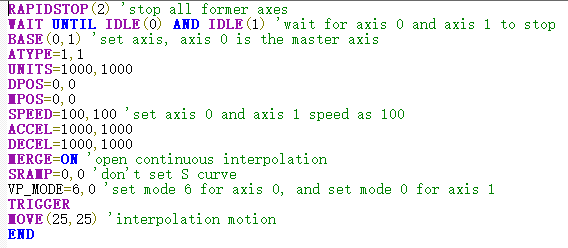

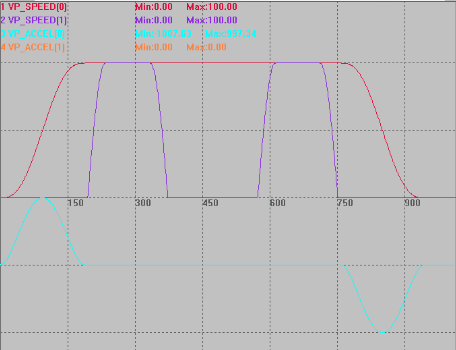

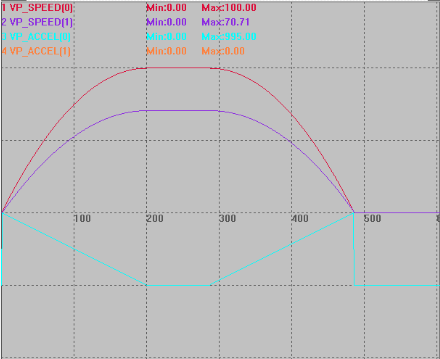

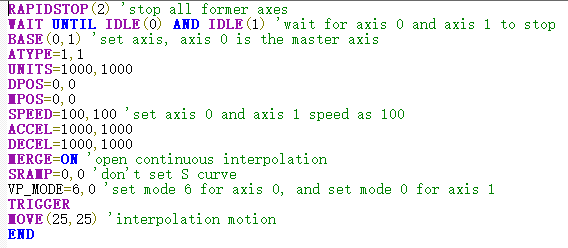

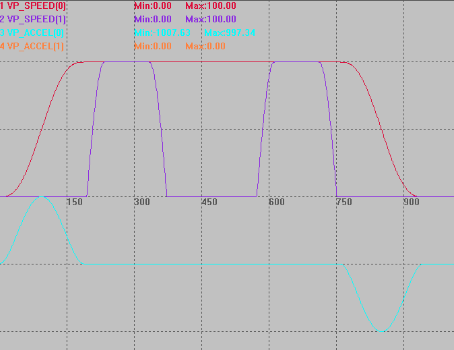

--set VP_MODE as mode 6, take multi-axis linear interpolation as the example--

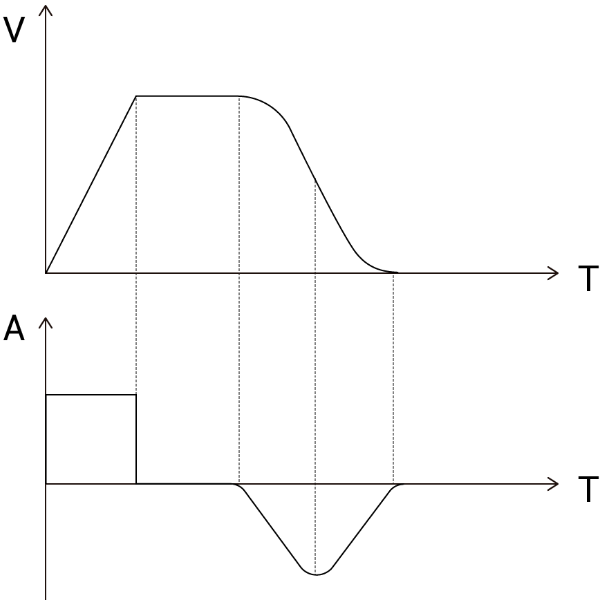

When VP_MODE is set to mode 6, only the deceleration phase is smoothed. When the S or SS curve is not set during the acceleration phase, the acceleration will reach the maximum value at the moment of power-on, and it will move with the set acceleration. When the SS curve is set in the deceleration phase, it can be seen from the figure below that the acceleration curve is decelerated smoothly, making the motion transition more natural and smooth during the deceleration phase.

This mode is suitable for continuous interpolation occasions to improve efficiency while ensuring smooth motion.

Note: since this movement is an interpolation movement, axis 0 is the main axis, so the speed and acceleration curves can be based on the main axis.

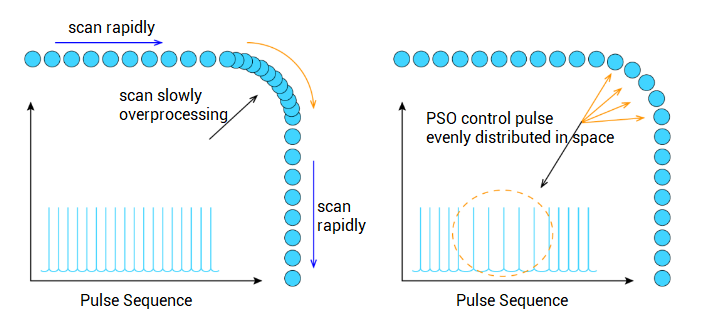

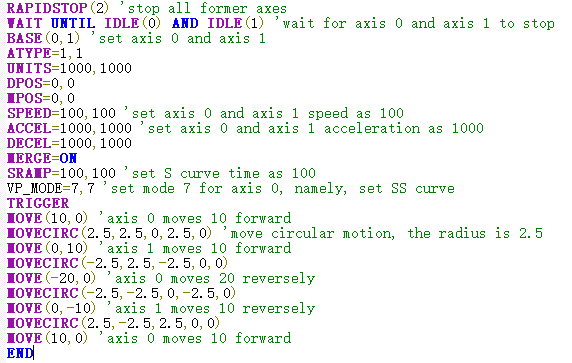

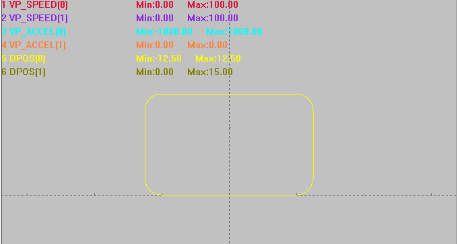

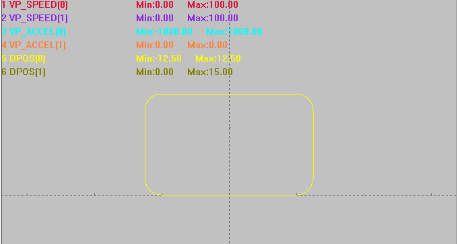

--set VP_MODE as mode 7, take track processing in lithium battery industry as the example--

VP_MODE is set to mode 7, and the image after smoothing the SS curve is as follows, which can be compared with the VP_ACCEL acceleration curve (light blue line) in the figure below. It is suitable for occasions with large motion jitter.

Note: since this movement is an interpolation movement, axis 0 is the main axis, so the speed and acceleration curves can be based on the main axis.

Interpolation trajectory of axis 0 and axis1 under XY mode:

--SS curve is not set--

SRAMP=100,100 'set S curve time as 100

VP_MODE=0,0

'cancel SS curve

It can be seen from the sampled waveform, it moves according to current S curve.

From this, it can be compared that VP_MODE=7, the speed curve of SS acceleration and deceleration of axis 0 and axis 1 is softer.