Pulses belong to parallel communication, but EtherCAT belongs to serial communication, then communication delay may be produced, synchronization of bus is worse than pulses?

Answer:

Actually it is opposite, EtherCAT doesn't equal to EtherNet, and synchronization between master and slave stations of EtherCAT doesn't coordinate through arrival time of data frame. From order issuance, EtherCAT synchronization is better.

There is 1000M bus, which is 10 times of 100M, therefore, our synchronization also is better than EtherCAT ?

Answer:

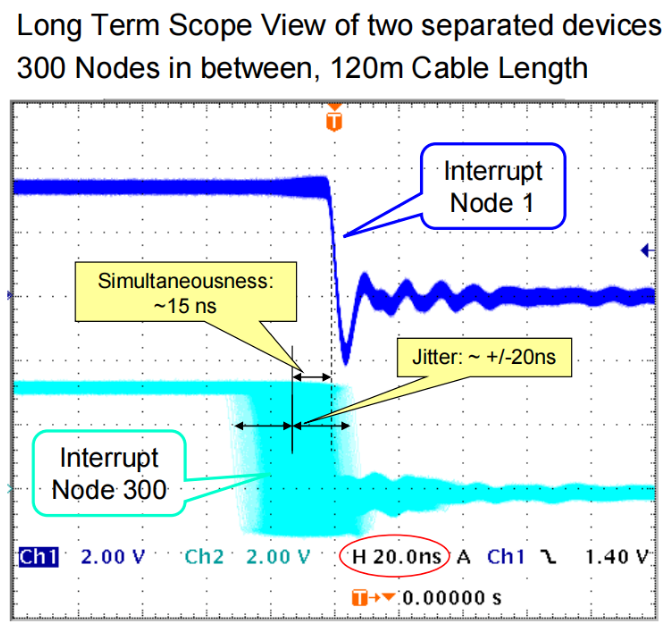

EtherCAT is extremely advanced fieldbus, and the distributed clock brought by specialized communication chip (ESC) to achieve synchronization of each slave station tasks, the synchronization error is <<1us (it should be 20ns in theory).

Next, let's learn deeply.

EtherCAT is an open and advanced fieldbus developed by the EtherCAT Foundation based on Ethernet. It ensures efficient and reliable data transmission through a series of unique mechanisms.

And EtherCAT only needs to use a 100M network cable to realize data transmission. The common topology structure is daisy chain, namely, the master station (controller) is connected to the first slave station (motor, IO module, etc.), then the first slave station is connected to the second slave station, connect continuously. In addition, EtherCAT also supports other topologies.

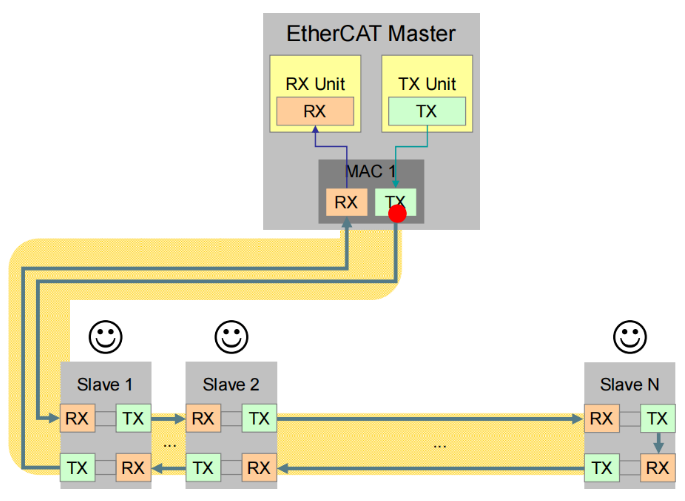

Although you only see one network cable connected, the 100M network cable actually contains 4 lines, two of which are used to output data (TX), and two are used to return data (RX). Therefore, in fact, one loop is formed internally, as shown in the figure below.

The EtherCAT master station needs to use a real-time operating system + standard Ethernet chip + EtherCAT protocol stack, and the slave station needs to use a special communication chip (ESC) to ensure high-speed and stable communication.

Therefore, although their external interfaces are all network ports "RJ45 interface", EtherCAT and EtherNET are very different at the hardware level, not just the difference in the data layer.

During the official work of EtherCAT (PDO communication), only one data frame is transmitted at high speed between the master station and the slave station. When passing through each slave station, each slave station takes down the required data, such as, command position, control word, etc., then it inserts the data that needs reporting (feedback position, motor status, etc.). It is the same principle as one high-speed train has to pick up and drop off passengers at every station.

But it is faster than high-speed rail, EtherCAT processes data in flight through a dedicated chip (ESC), instead of waiting until the data is completely received before processing and sending. Therefore, high-speed data exchange can be achieved.

As mentioned before, the EtherCAT slave chip (ESC) has a distributed clock. What exactly is this?

The field bus is generally serial communication, so there must be a time difference when reaching each slave station. No matter how fast the high-speed rail is, it cannot reach Shanghai and Kunshan at the same time.

So how does EtherCAT ensure that the slave stations act in unison without falling behind? The answer is the distributed clock.

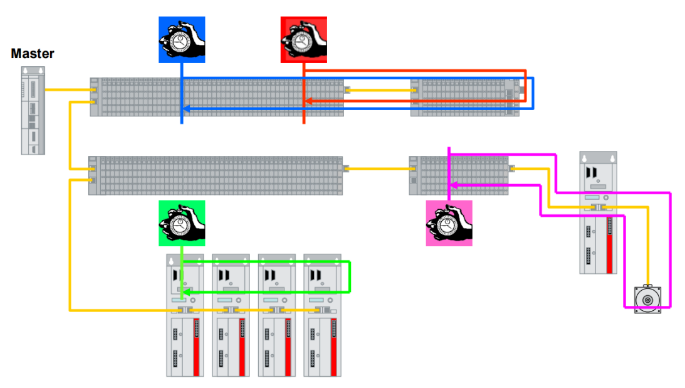

The EtherCAT master station will select the first slave station with clock (DC) function as the clock master station (DC Master), and each slave station will be synchronized according to the time of the clock master station. In this way, if multiple motors do multi-axis interpolation, they can refer to the precise clock signal to sample at a unified time (collect command data), and act at a unified time, like this:

Each slave station has its own watch, like those police and gangster movies, the officer said: Now put on the watch, and act together at 8:50 in the evening (the expression must be serious when you say it).

Of course, the clock (DC) of EtherCAT is not dialed manually, but EtherCAT calculates the clock error between each slave station through a complex mechanism, then corrects it in real time to ensure that the time keeps a very small error between each slave station (much less than 1us, the official test data is about 20ns).

Going back to the original question, compared with the pulse motor, the pulse drive receives the data at the same time, but there is no way to coordinate the clock signal between the drives, so it is inferior to EtherCAT in theory.

In fact, most applications are restricted in the performance of motor debugging, so our feelings are not obvious, but EtherCAT has already laid the foundation for precise synchronization at the bottom layer.

Some friends may say, don't brag, I know that the next generation standard of EtherCAT is EtherCAT G, which is also the Gigabit bus, which means Gigabit is better. However, the fact is that EtherCAT G is not designed to improve synchronization ( It is already very good), what is its significance, it will be introduced in detail in the next technical support article).

In addition to the above advantages, EtherCAT has many other advantages, including simple wiring, convenient interference checking, no trouble of losing pulses, rich transmission data (such as absolute value data, torque status), etc.

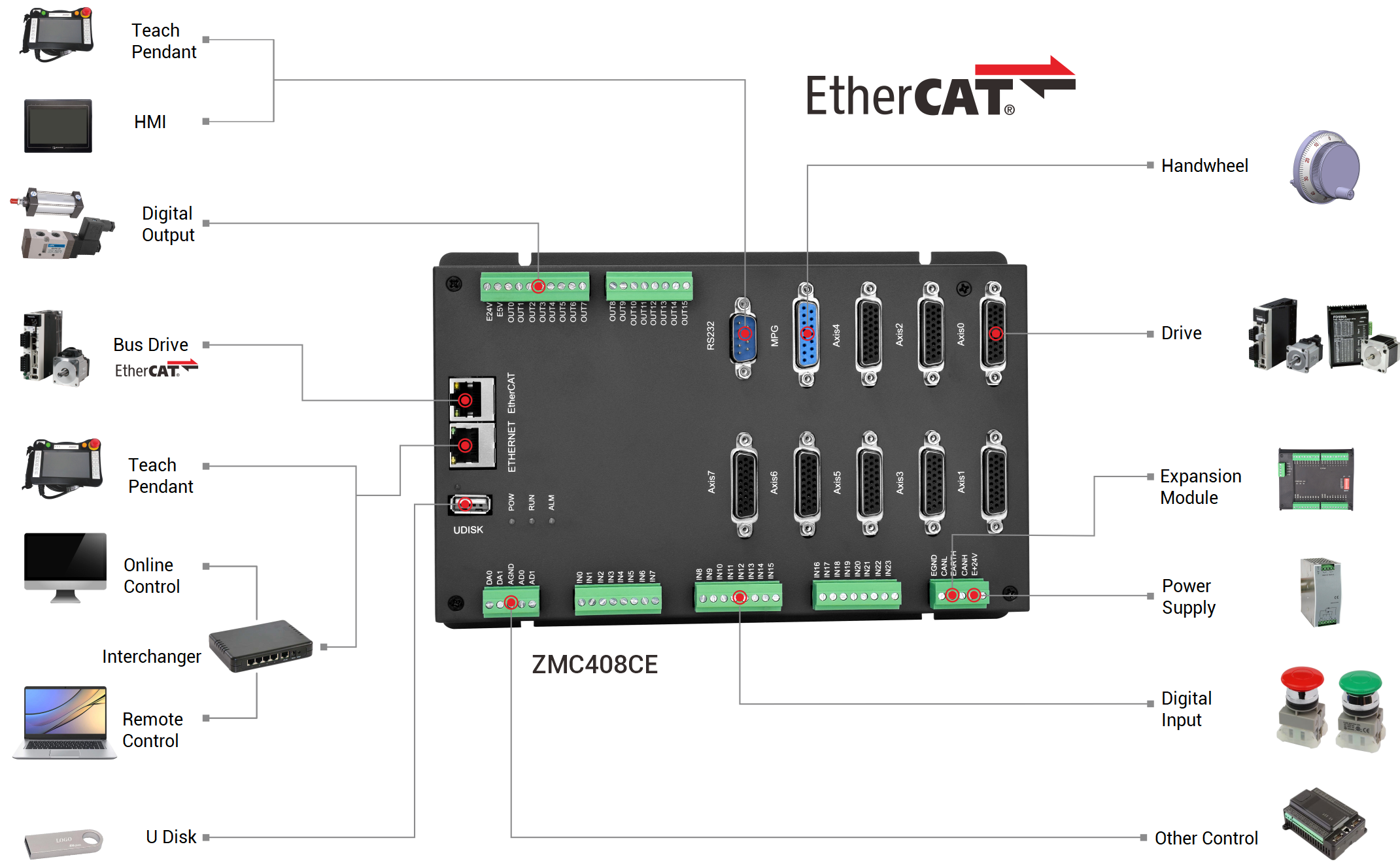

Finally, of course, we would like to recommend our Zmotion EtherCAT bus motion controller "ZMC408CE" for you. Zmotion is the first to support EtherCAT in China. Currently, it supports the max number of slave stations and it is with the best compatibility. What's more, there is a video introduction for you, please enjoy it and hope you like it.

ZMC408CE Product Highlights

1. High-performance processor, computing speed, response time and scan cycle, etc. are can be improved.

2. One-dimensional / two-dimensional / three-dimensional, multi-channel visual flying shooting, high speed and high precision.

3. Position synchronization output "PSO", precise dispensing glue volume control and laser energy control in continuous trajectory processing.

4. Multi-axis synchronous control, multi-coordinate system independent control, etc.

5. EtherCAT synchronization cycle can reach 125us.

6. Support hybrid interpolation between EtherCAT bus and pulse axis.

7. Linear interpolation, circular interpolation in any space, helical interpolation, spline interpolation, etc.

8. Flexible application, it can be developed by PC host computer, and can also run independently offline.

ZMC408CE Production Introduction

ZMC408CE is one high-performance EtherCAT bus motion controller launched by Zmotion technology. Advanced FPGA technology is used to achieve hardware position comparison output and precision output, to ensure excellent performance and stability of continuous trajectory processing, and to capture dynamic data in real-time, then in this way, control precisely can be realized and production efficiency and quality can be improved through our Zmotion ZMC408CE EtherCAT bus motion controller.

ZMC408CE supports mixed interpolation between EtherCAT and pulse axis. And it can run offline or online. Except mixed interpolation, it supports ZDevelop + multipple kinds of advanced host computer hybrid programming, then it can achieve point to point motion, electronic cam, linear interpolation, circular interpolation, continuous trajectory processing and 30+ robot models control.

there are 8-32 axes.

there are EtherCAT, CAN, RS232, RS485, EtherNet and U Disk interfaces.

there are 24 DI, and 4 are high-speed color patch latch.

there are 16 DO, and 8 are hardware comparison output PSO, 8 are high-speed PWM.

there is one specialized handwheel input interface.

ZMC408CE Controller Multi-dimensional Multi-channel PSO

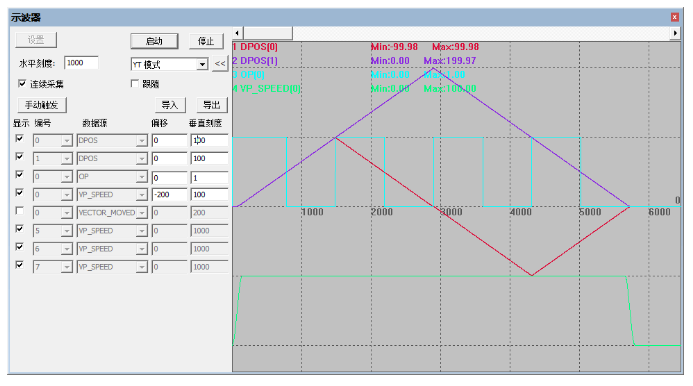

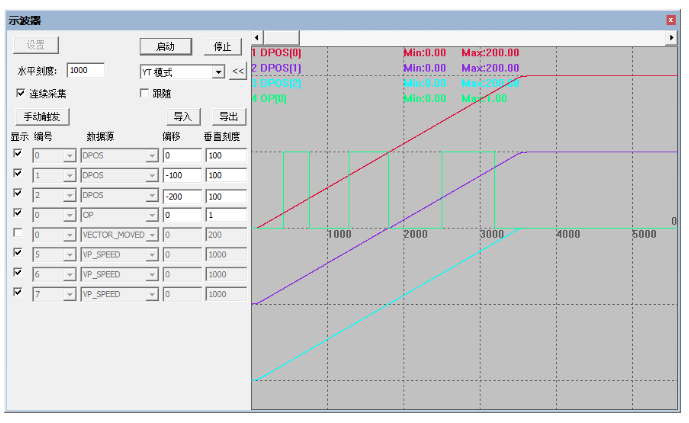

1. 2D PSO Output:

2. 2D PSO Output:

ZMC408CE Controller Development

1. support PLC, Basic and HMI programming methods.

2. PC upper computer programming, C#, C++, LabVIEW, Matlab, Qt, Linux, VB.Net, Python

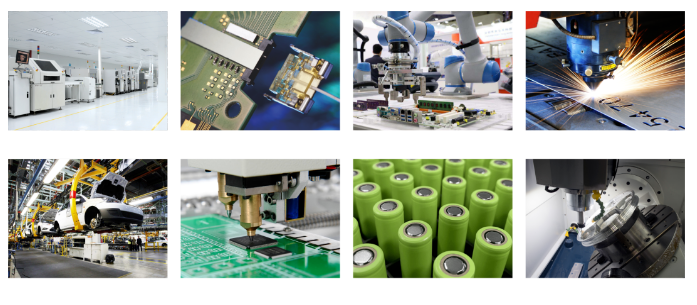

ZMC408CE Controller Applications

It is applied in large-scale processing and assembly production lines in the fields of 3C electronics, semiconductors, new energy, photovoltaics, automobiles, medical care, dispensing equipment, assembly lines, etc.

ABOUT ZMOTION

That's all, thank you for your reading -- How to Choose the Bus Motion Controller in the era of industrial Ethernet?

For more information, please pay close attention to "Support" and "Download" , and there are other platforms about Zmotion - Youtube & LinkedIn & Twitter & Tiktok & Facebook, including technical information (development environment, routine code), product showing, company development, etc.

Hope to meet you, talk with you and be friends with you. Welcome!

This article is edited by ZMOTION, here, share with you, let's learn together.

ZMOTION: DO THE BEST TO USE MOTION CONTROL.

Note: Copyright belongs to Zmotion Technology, if there is reproduction, please indicate article source. Thank you.

Zmotion Technology focuses on development of motion control technology and general motion control products, it is a national high and new technology enterprise. Due to its concentration and hard work in motion control technology, ZMOTION already become one of the fastest growing industrial motion control companies in China, and is also the rare company who has managed core technologies of motion control and real time industrial control software completely. Here, Zmotion provides motion controller, motion control card, vision motion controller, expansion module and HMI. In addition, there is one program software developed by Zmotion -- ZDevelop. It is a good choice for you to program and compile. And program through upper computer, there is PC manual.

Zmotion Technology provides motion control card, motion controller, vision motion controller, expansion module and HMI. ( more keywords for Zmotion: EtherCAT motion control card, EtherCAT motion controller, motion control system, vision controller, motion control PLC, robot controller, vision positioning...)

Have a good day, best wishes, see you next time.