Home / News / Product News

New crown pneumonia is raging around the world. As of now, the number of confirmed cases of new crown pneumonia in the world has exceeded 1.56 million. Europe is still the center of the new crown pandemic, and the shortage of masks and medical supplies have become global problems. The overseas epidemic continues to spread, and masks have become one of the necessities of people's epidemic prevention and control measures. Faced with the huge gap in supply and demand, ZhengMotion technology combines its own advantages to launch a new N95 mask machine EtherCAT bus control system application solution to help the N95 mask machine full-speed production.

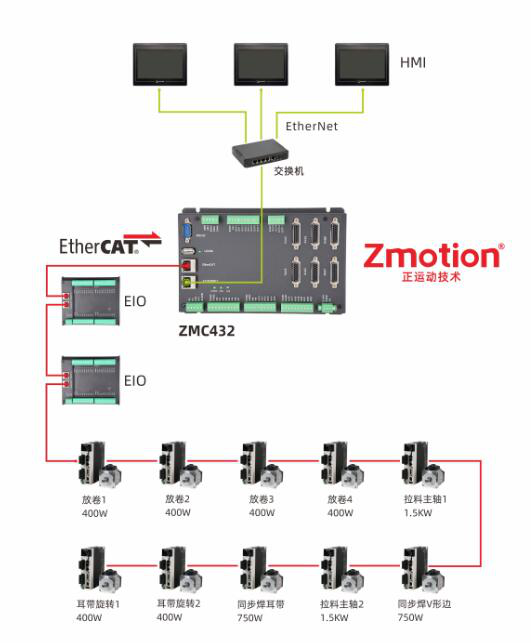

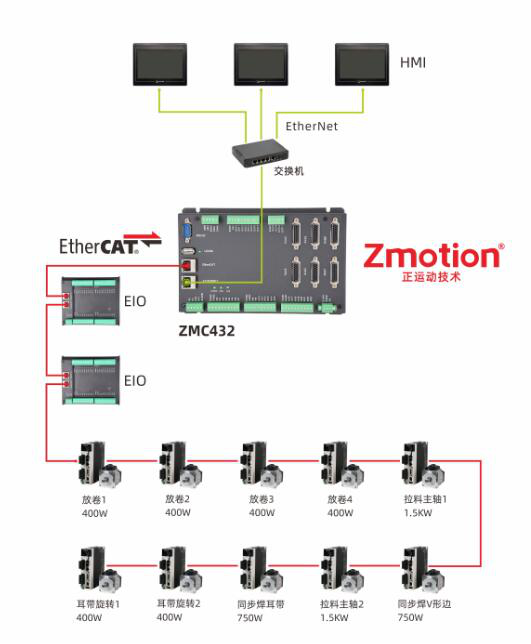

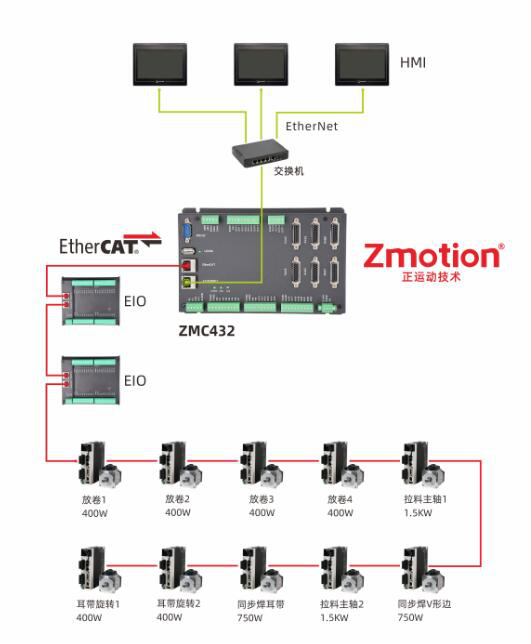

Positive motion technology ZMC432 high speed and high precisionEtherCATBus scheme

(Scheme topology diagram)

For mask manufacturers, the most important thing is the increase in production capacity. An important factor is the processing speed and production efficiency of the equipment. Motion control products and systems play an important role in it. Positive motion technology high-speed and high-precision EtherCAT bus solution mainly includes EtherCAT bus motion controller ZMC432, EtherCAT bus expansion module EIO1616MT and other products.ZMC432 controllerMainly responsible for controlling the operation of all EtherCAT servo axes and ultrasonic equipment,The programming is convenient and simple. The electronic cam function and the chase cutting function are realized through the optimized motion control algorithm, which can increase the production speed and meet the accuracy and speed requirements of the fully automatic mask production. In addition, this solution adopts the industrial Ethernet bus technology for high speed and high speed. The features of precision, multi-axis synchronization, etc. can help customers greatly save debugging man-hours, increase the number of masks produced per unit time, and improve the welding accuracy of mask earbands.

ZMC432 product advantages

· The fastest EtherCAT bus synchronization cycle of 125us supports up to 32-axis motion control;

· Onboard 24 points input + 12 points output, onboard 6 pulse outputs and 6 encoder inputs;

· Support Ethernet interface debugging program and ModbusTCP, RS232 and RS485 support ModbusRTU communication;

· Support EtherCAT bus + pulse mixed use, which is convenient for pulse type stepper driver;

· Support electronic cam, electronic gear, position latch, synchronous follow, virtual axis, precise output and other functions;

Application of electronic cam in the cutting of mask machine

In the N95 mask cutting process, the wheel cutting process of the electronic cam can be used to complete the high-speed cutting, and the fixed length of the cutting can be set through the program to realize the efficient debugging of the process.

Follow-up shearing application in earband welding and pad printing process

In order to improve production efficiency, the fabric is always in the conveying state during production. During the welding and printing process, it is necessary to ensure that the welding equipment and pad printing equipment and the fabric are in a relatively static and synchronized state, so the ear welding mechanism and the pad printing mechanism are required It advances synchronously with the fabric, and returns separately from the fabric after welding and printing are completed.

The positive motion technology N95 mask machine program adopts the MOVESLINK automatic cam command. A simple few lines of code can complete the chase cutting and wheel cutting processes, which saves debugging time and reduces the difficulty of debugging.