Exhibition Name:

China International Industry Fair CIIF 2025

(abb.: Shanghai CIIF)

Exhibition Date:

2025.9.23-2025.9.27

Exhibition Address:

National Exhibition & Convention Center

(Shanghai, China)

Booth No.:

6.1H-E261

2025 Shanghai CIIF will be held in National Exhibition & Convention Center (Shanghai China) during September 23-27, 2025. And in this 25th CIIF, except Zmotion main motion controllers, new products and its solutions will be shown. Welcome to CIIF booth 6.1H-E261. Then today, Zmotion motion controller specialized for laser galvanometer “ZMC408SCAN-V22” will be introduced.

ü

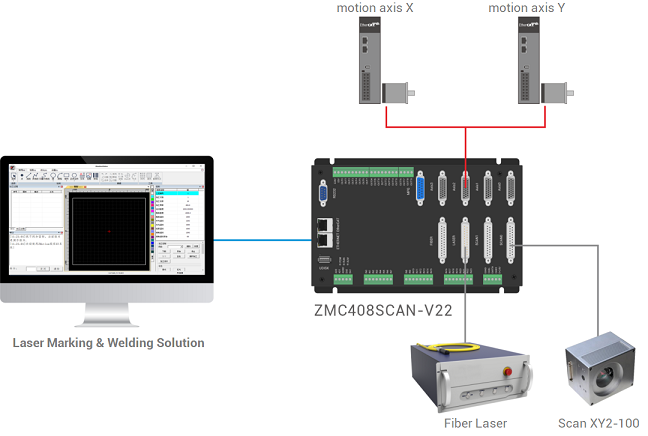

Zmotion Laser Galva Solution: Large-Area Linked Laser Marking & Welding

ü

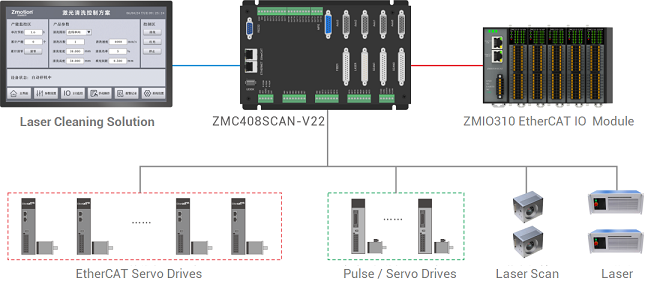

Zmotion Laser Galva Solution: Laser Cleaning

ü

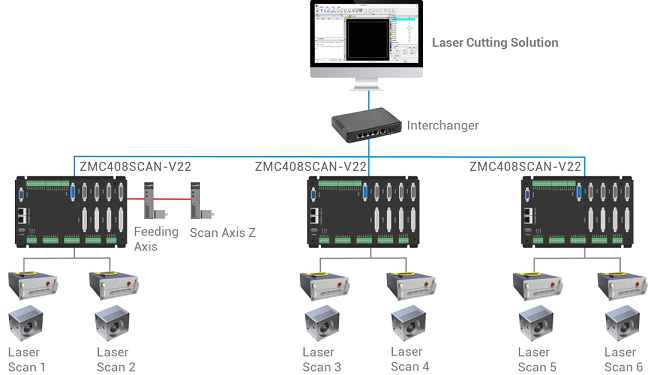

Zmotion Laser Galva Solution: Laser Cloth Cutting with Multi-Scan

PS:

Zmotion New Products & 2025 CIIF: https://www.zmotionglobal.com/news_info_152.html

Zmotion High-Speed & High-Precision Real-Time EtherCAT Motion Control Solution: https://www.zmotionglobal.com/news_info_153.html

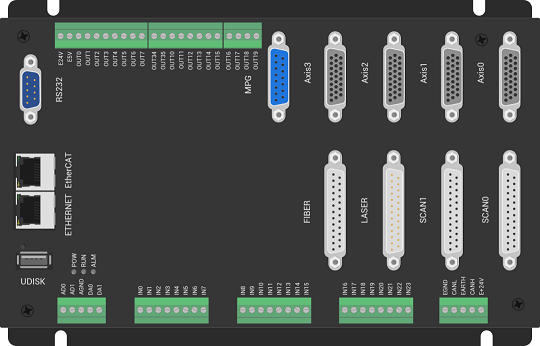

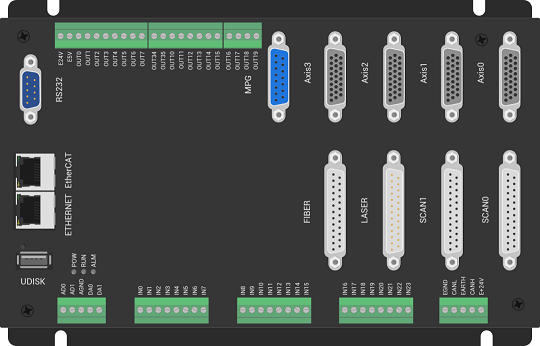

Zmotion Laser Galvanometer Motion Controller “ZMC408SCAN-V22”

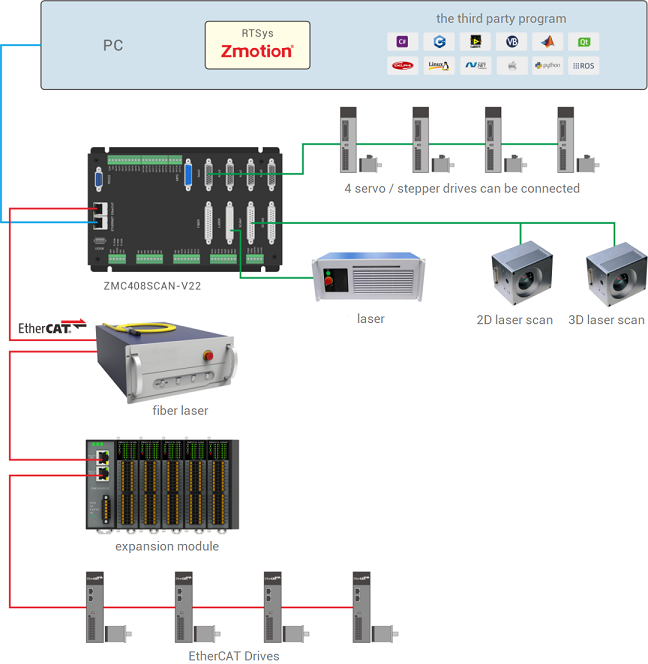

ZMC408SCAN-V22

is one Zmotion EtherCAT motion controller that can help you

achieve high-speed & high-precision EtherCAT motion control + laser galvanometer solutions!

*High Integration*

One ZMC408SCAN-V22 integrates

“laser control”, “galvanometer control”, “axis control”, with “IO control”

. Then, your hardware costs can be saved, and system will be more stable, respond speed is faster due to its high-integration.

*Real-Time Control*

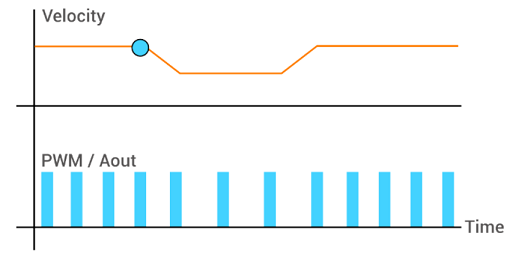

ZMC408SCAN-V22 supports real-time motion control functions, like, high-speed

PSO, PWM, speed look-ahead

, etc., which can ensure smooth processing trajectory, improve processing quality and capacity.

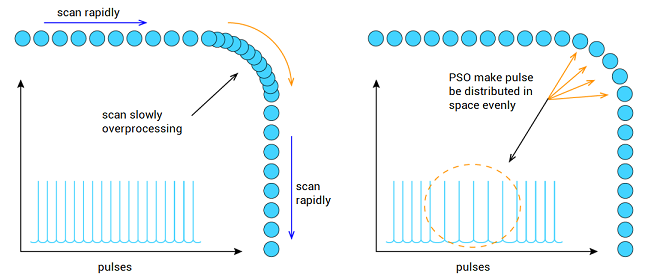

high accurate PSO, equal-space output

synchronized output (PWM, DA, SPEED)

*Easy to Use*

Zmotion provides you with all kinds of libraries for developing your laser system easily, for example, the graphic library, 3-axis / 4-axis linked library, speed look-ahead library, etc.

*Intelligent Synchronized Control Algorithm*

Also, there is Zmotion own

graphic trajectory planning algorithm

, which can do synchronous motion between the scan platform and motion platform, improving the processing efficiency and accuracy.

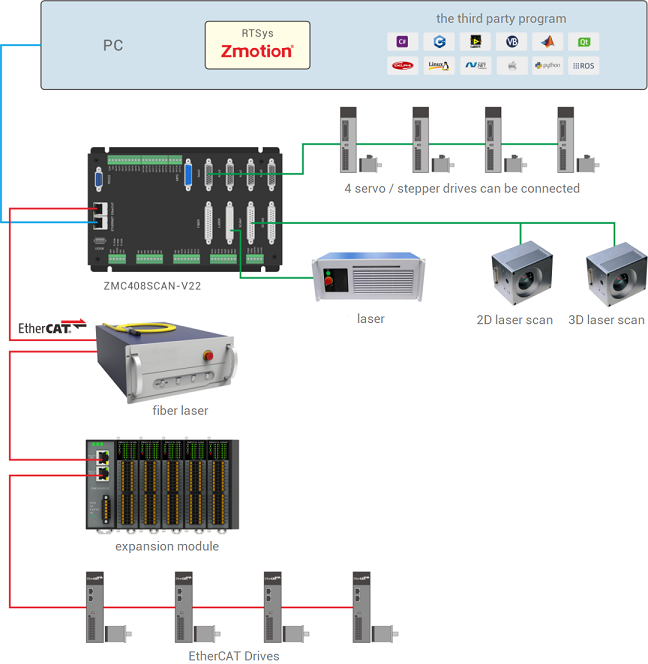

“ZMC408SCAN-V22 is mainly for laser galvanometer area. And compared to traditional laser processing solution, Zmotion ZMC408SCAN-V22

can be applied in all kinds of requirements flexibly, for example, laser cutting, laser marking, laser welding, laser cleaning, etc., and the

processing trajectory could be smooth.

Let’s see some related solutions”

Zmotion Laser Galvanometer Motion Control Solutions

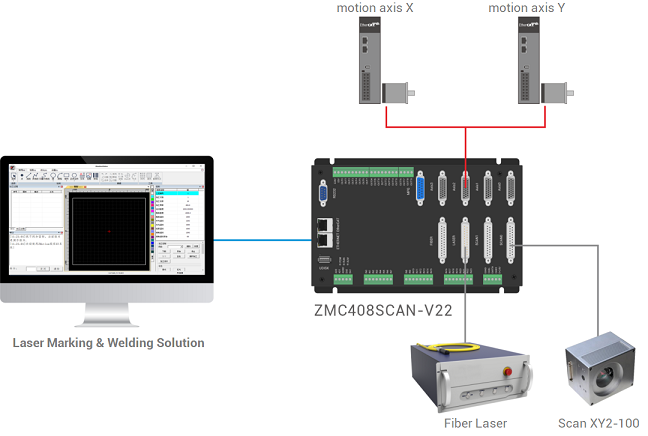

[Large-Area Linked Laser Marking & Welding]

It can be seen that one ZMC408SCAN-V22 is used to control the fiber laser, two scan axes, and two motion axes.

B.

Solution Advantages

l

Multi-Scan Synchronized Control:

multiple groups of scans can be run synchronously, and workpieces can be different sizes, obviously, to

make efficient laser processing.

l

High-Speed & High-Precision:

it supports laser + galvanometer + motion control, and it can automatically correct the deviation, which ensure the processing be

fast, and

less defect products at the same time.

l

With Laser API:

Zmotion provides the laser specialized API, there are many graphic processing and technology optimization functions, then your production process will be

easier.

l

Servo Axis & Scan Axis Linked:

axes can be linked to process complex shapes, during the motion, it can do precise positioning for laser beam and do dynamic tracking, the motion also becomes

more stable.

l

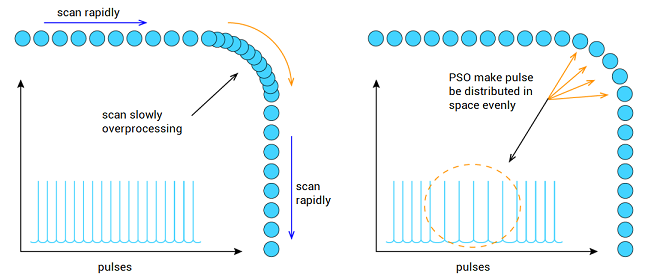

High Accurate PSO Algorithm:

PSO makes the laser output equally even when it is at the corner, no need to worry about “over” / “less” / “no” problems. To achieve

higher laser processing quality.

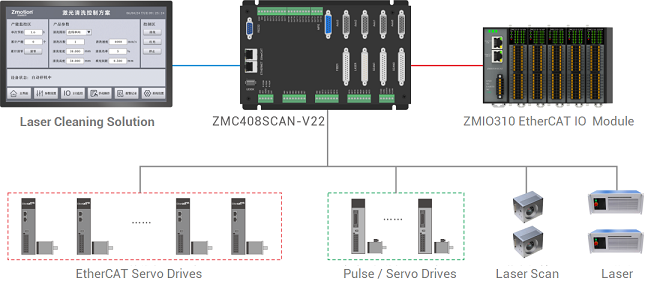

[Laser Cleaning Motion Control Solution]

The same as above linked solution, one ZMC408SCAN-V22 controls motion axes (EtherCAT * pulse are OK), laser galvanometers, lasers. Except that, if the controller itself IO resources are not enough, the

IO expansion module also can be connected to reach needed IOs.

For Zmotion IO modules, there are many specifications for your specific project requirements. According to your controller, you can choose EtherCAT modules or CAN modules.

Zmotion IO Modules: https://www.zmotionglobal.com/pro_class_54.html

B.

Solution Advantages

l

With Graphic Operation Interface:

the “laser cleaning debugging software” is configured. Then, after setting cleaning and laser parameters, one task can be made directly. Obviously, operation accuracy and efficiency both are

increased.

l

Environmental-Friendly & Consumable-Free Process:

no need abrasive materials or chemical cleaning agents, the efficient cleaning can be performed through laser ablation. This significantly reduces dust and waste, eliminates chemical pollution, and achieves both

high efficiency and environmental protection.

l

Flexible Laser Power Config:

you could precisely adjust the laser energy and pulse time according to different materials. And the materials can be kept well because of non-touch cleaning.

l

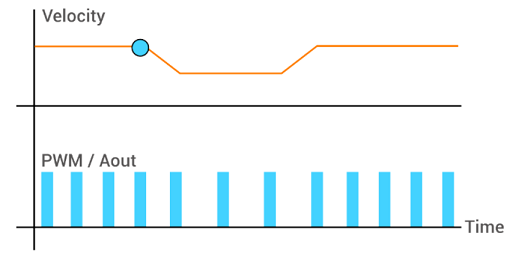

Synchronized Control of Laser Power & Motion Speed:

while cleaning, the laser power and the movement speed can be synchronized. You can real-time adjust them to make the consistent cleaning effect, “more” / “less” situations can be avoided.

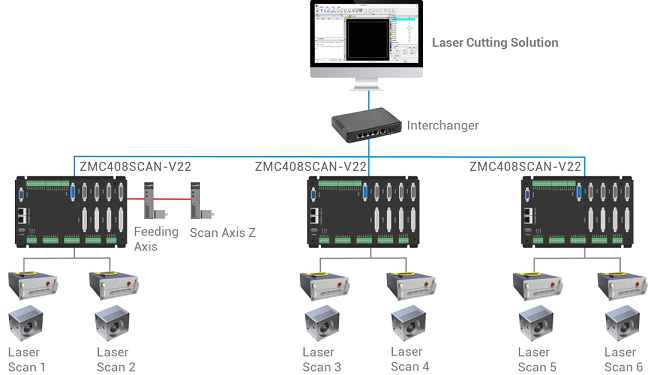

[Laser Cloth Cutting Solution with Multi-Scan]

When you need multiple groups of scans to work together, ZMC408SCAN-V22 can do that. Use one interchanger to connect them at the same time, then design needed contents.

B.

Solution Advantages

l

High-Accuracy Cutting:

through the multi-scan system, it can precisely cut the cloth, each shape and pattern could be met. In this way, it won’t produce too much waste,

improving the material utilization.

l

Strong Graphic Processing Function:

it supports advanced software algorithm, which can process complex graphic easily, including the details.

l

High-Efficiency & Energy Saving:

its algorithm ensures the cutting quality, and the energy can be saved at the same time through optimized energy control function.

l

High Automation:

the automatic loading and unloading system, the intelligent typesetting software are supported, which means the production line efficiency is increased.

l

Convenient Maintain:

it is easy for you to clean and store because of its tight structure.

Above introduced “laser galvanometer motion control solutions” of ZMC408SCAN-V22 and high-speed & high-precision pc-based motion control solutions, etc. all will be shown in

25th CIIF during 9.23 – 9.27. And Zmotion booth is

6.1H-E261. If you have motion control needs, let’s help you meet the requirements.