Zmotion technology motion control technology (motion controller) in dispensing industry is extremely mature now. There are many applications we did successfully, for example, LED spraying, speaker following dispensing, PCB following dispensing, glue path detection, etc., even you can choose machine vision function together based on one hardware only.

No matter motion control only, or machine vision and motion control integrated, our controllers support rich functions but easy to learn, easy to use:

--method 1--

PC programming languages API function library is provided, main languages are OK, C++ / C# / LabView / Python, etc.

Library & manual & examples can be obtained from “Zmotion Download”.

--method 2--

Zmotion own RTBasic language in own development platform RTSys.

You can test examples under simulator (without real motion controller).

What’s more, complete solution you can use directly, static dispensing, dynamical dispensing, 5-axis linkage dispensing, and so on. No complex codes editing anymore, your machine can be run after our standard dispensing solution evaluation and learning.

Let’s enter main theme.

One new application in dispensing industry will be shown, to drip medicine.

Today, take “gunpowder” medicine product as the example, introducing Zmotion dispensing motion control and machine vision technologies – how & why it achieves precision dispensing.

Electronic Detonator (digital electronic detonator) uses electronic control module and specialized detonation equipment to control detonation.

The features are obvious:

l Highly-Safe

l Highly-Reliable

l Highly-Precise

l Highly-Efficient

l Controllable & Detectable

Before detonating the gunpower head by the electronic detonator, blending the original materials according to a certain quality ratio at first, then, mixing with adhesives.

For medicine-dripping dispensing, the drop volume must be highly accurate. However, hard to reach us level precision under traditional manual or mechanical filling.

Compared to that, vision dispensing machine updates “accuracy, intelligence, flexibility”, which solve 2 important problems, efficiency and quality. For manufacturers, less cost brings higher productivity.

Traditional Dispensing Equipment to Drip Medicine | |

Traditional Dispensing Machine | l What is It? Ø Be composed of “dispensing control module”, “motion execution module”, “dispensing needle”, “sensor”, etc. Ø Its working principle is based on motion path control programmed with preset points and driven by air pressure, thereby achieving precise extrusion of the glue liquid and collaboratively completing precision dispensing. l Problems n glue valve leakage n unstable glue delivery rate n poor glue consistency n glue breakage [directly influence quality & efficiency] |

Precision Dispensing Technology | |

3 Technical Challenges | Ø high-speed & high-precision Ø adaptable fluid medium characteristics Ø complex dispensing path |

Strict Requests | Ø device mechanical structure accuracy Ø electronic control system performance Ø operation system usage |

Zmotion EtherCAT Vision Dispensing Machine to Drip Medicine | |

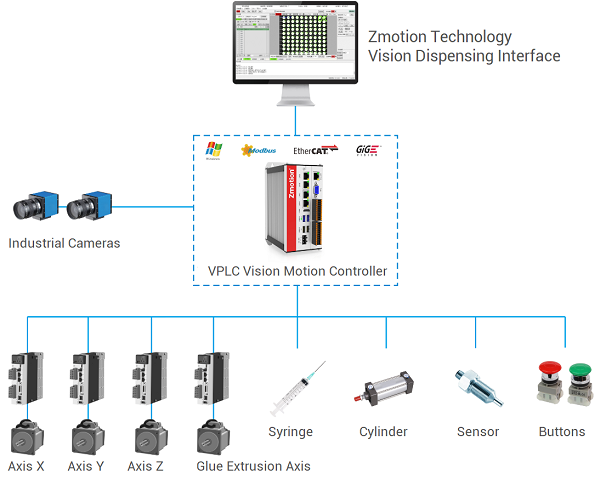

Zmotion Dispensing Control Solution | ü integrate machine vision with motion control ü multi-axis synchronized control ü rich interfaces ü power functions [high-integration | no need vision IPC, cost-effective & small volume, easy to install, save the space] |

| |

*Zmotion Machine Vision Dispensing | Drip Medicine*

Let’s see details.

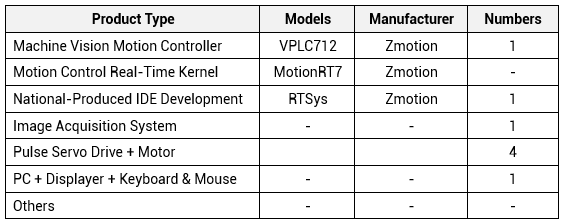

A. Solution Hardware: Zmotion Machine Vision Motion Controller

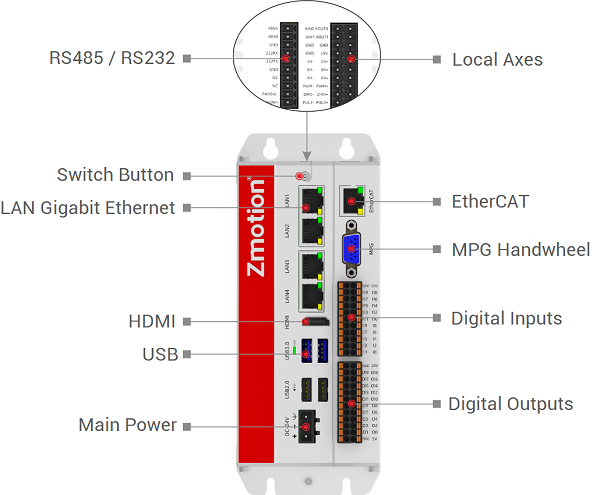

Zmotion VPLC712 vision motion controller is one x86 Windows EtherCAT controller (also be one IPC), which can do complex motions conveniently, why?

*hardware high-integration*

*hardware simple structure*

*software PLC inside*

*software real-time*

For more details, please refer to “VPLC712 EtherCAT Vision Motion Controller User Manual”.

Except this, there are Linux vision motion controller, VPLC532E.

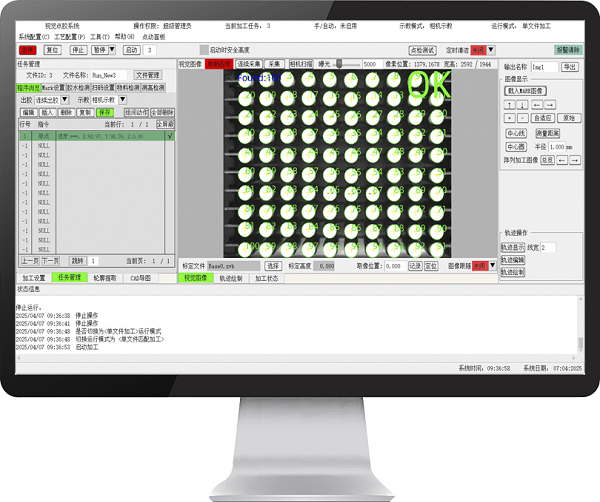

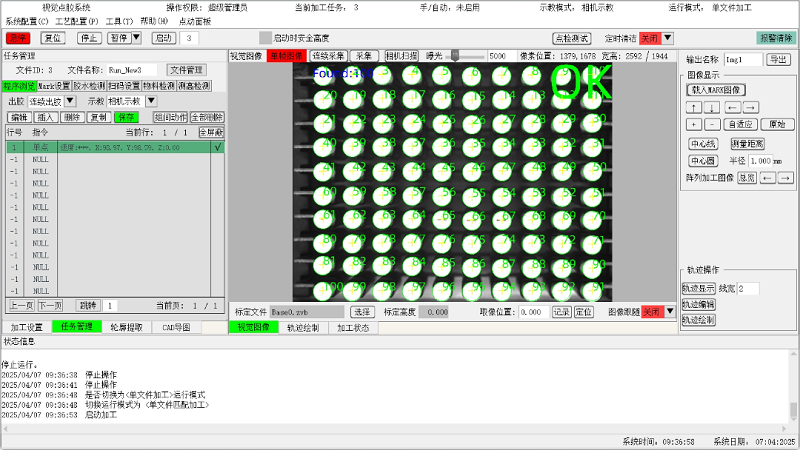

B. Solution Software: Zmotion Machine Vision Motion Dispensing Software

It is done by our free IDE development software RTSys.

Why choose Zmotion this solution?

*Complete Functions*

It can dispense point, line, arc, continuous segment, array, etc.

Technology function includes early / delayed to switch on / off dispensing, manual teaching, camera teaching, etc.

*Machine Vision Correction*

It can automatically recognize product at any position and angle, then do dispensing.

*Friendly Operation Interface*

Easy to program and debug, it can do teaching and motion in vision image.

A. Machine Vision

“template matching” function is mainly used.

At first, recognize the gunpowder head through preset features, like, shape, size, Mark point.

Then, get its coordinates, make it arrive at processing area.

At least, dispense, drip it one by one.

B. Motion Control

a. Precise Switch Control

Adjust dispensing valve ON & OFF and needle trajectory accurately, including delayed open, delayed close, early close, lift height, etc., no more wire drawing and glue stacking.

b. Advanced Accurate Control

--dispensing specialized look-ahead--

It can do look-ahead processing for dispensing motion trajectory, then optimize and smooth special-shape path.

Sometimes, dynamic speed is required. Look-ahead the linear speed to avoid unnecessary acceleration and deceleration, high-speed trajectory can be made.

--S Acceleration & Declaration--

Reduce device vibration, promote motion smoothness.

--PSO Position Synchronized Output--

Precisely synchronize spraying glue with glue valve motion trajectory.

C. Solution Advantages

(1) Glue Precisely Controlled by Motor

Use motor as pressure source to ensure accurate dispensing

(2) Not Rely on Compressed Air Source

There is switch glue, don’t need compressed air source.

(3) Glue Volume Precisely Controlled

It can real-time adjust the volume, make sure they are used appropriately. The error will be controlled extremely small, getting high-precision dispensing.

(4) Motor Back Suction for Anti-Drip & Anti-Wire

The motor can suck inversely, easy to solve leakage problem.

(5) Vision Positioning

Through camera, real-time positioning the gunpowder position and automatically generate processing point, which means no need to do array programming.

Thank you for your reading.

About dispensing applications, there also are:

[ Zmotion Vision Motion Controller LED Adhesive Spraying Solution ]

[ Vision Motion Controller | Dispensing Glue-Path Detection ]

[ Vision Motion Controller Application on Speaker Following Dispensing ]

[ Gantry Dynamic Dispensing by Zmotion Machine Vision Motion Controller ]

……